Battery Process

More Custom Items

Xiaowei New Energy

Laboratory research equipment for the front part process includes: vacuum mixing, viscosity tester, slurry processing system, coating, roller pressing, drying oven, etc. These equipment can be used to quickly and systematically complete the production of battery electrodes. This type of equipment is widely used It is used for university laboratory research, battery research in scientific research institutions, and research on battery cycle times and performance, etc.

Battery Process: Lab Electrode Preparation Process

Laboratory research equipment for the front part process includes: vacuum mixing, viscosity tester, slurry processing system, coating, roller pressing, drying oven, etc. These equipment can be used to quickly and systematically complete the production of battery electrodes. This type of equipment is widely used It is used for university laboratory research, battery research in scientific research institutions, and research on battery cycle times and performance, etc.

Battery cathode and anode material mixing

This high-efficiency equipment integrates vacuum mixing and dispersion. It is suitable for the mixing process of positive and negative electrode slurries in battery laboratory research. It is completely bubble-free.

Controlling cathode and anode material uniformity

It is widely used in chemical, food, pharmaceutical, paint, cosmetics and other industries to evaluate the fluidity and viscosity characteristics of liquids.

Remove iron and improve slurry purity

This high-efficiency equipment integrates vacuum mixing and dispersion. It is suitable for the mixing process of positive and negative electrode slurries in battery experimental research. It is completely bubble-free.

Supply of coating slurry

The slurry supply system is convenient for storing and providing slurry during the coating process. The device is beautifully designed, has a speed-adjustable peristaltic pump, high-precision feeding, and is equipped with iron removal and vacuum filtration systems.

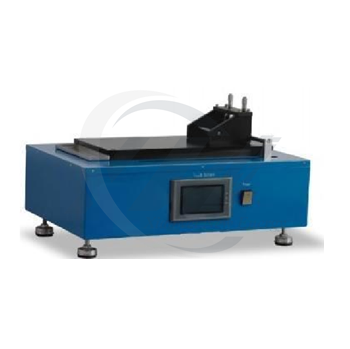

Battery cathode and anode material coating

The automatic coating dryer machine is widely used in various high-humidity coating research, and is widely used in crystal coatings, lithium/sodium battery material coatings, and coating technology under high temperature conditions.

Exhaust gas treatment

It is used to filter the solvent in the exhaust gas generated during the drying process of the coating machine to achieve the functions of dust removal and exhaust gas purification.

Increase battery electrode energy density

It is suitable for rolling of laboratory battery electrode, copper foil, aluminum foil, and a small amount of precious metals, especially suitable for rolling the thickness of lithium battery electrode.

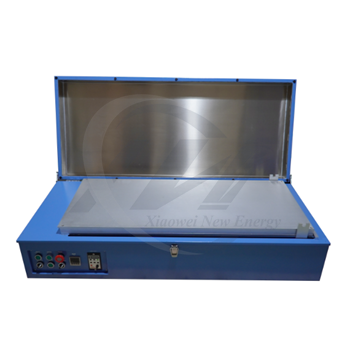

Battery material drying

Positive air drying oven specially designed for lithium batteries, reducing moisture in lithium batteries, drying positive and negative electrode materials, drying electrode, drying before packaging, drying before liquid injection, etc.