Products Description

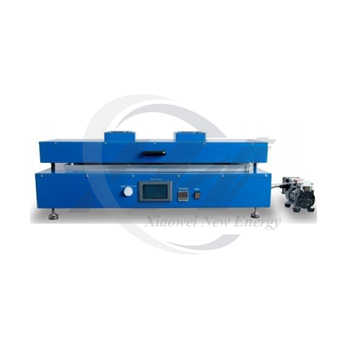

Lab coating machine is a compact Roll to Roll continuous coater for battery electrode sheets with a small size for battery research labs. The coating machine is with four Direction wheel in bottom, it can be removed easily for laboratory use.

Technical Parameters

- Source voltage: AC 110v/220v, 50HZ/60HZ;

- Power: 15KW;

- Coating mode: Continuous/ intermittent coating;

- Max coating width: 200mm;

- Applicable matrix data;

- Aluminum foil : 15-50um thickness, 50~350mm width, 27~135g/ ㎡ density,Can be customized;

- Copper foil : 6-20um thickness, 50~350mm width, 53~178g/㎡ density,Can be customized;

- Mechanical tape speed: Max7.5m/min, with accuracy ±0.1m/min;

- Coating speed: 0-750 mm / minute, adjustable;

- Coating roller accuracy: ≤1um;

- Double dry thickness accuracy error : <±4um;

- Single side dry thickness accuracy error : <±2um;

- Double coated alignment error : <±0.5mm;

- Average length of error : <±0.5mm;

- Roller inner diameter: Ø120mm;

- Struggle to control precision: <±0.3mm;

- Oven temperature: 150°C adjustable, with accuracy ±1°C, Independent PID adjustable;

- Weight: 400kg Dimension(L*W*H): 3600*1000*1200mm.

Product Features

- Plasma cleaning function optional;

- Can switch freely to achieve continuous and intermittent coating;

- Substrate tension control, transport stability, configuration correction device;

- Hot air oven, the upper and lower double-sided blowing, high-quality drying effect;

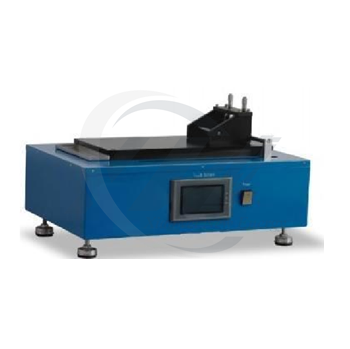

- Three-roll transfer coating, wider coating window;

- Comma scraper measurement, with precision adjustment agencies, access to high-precision coating;

- Power generation with analogue signal control, high accuracy ±0.3°C of the heating system and long life;

- PLC control,Touch screen operation, easy to use;

- Optional solvent recovery device.