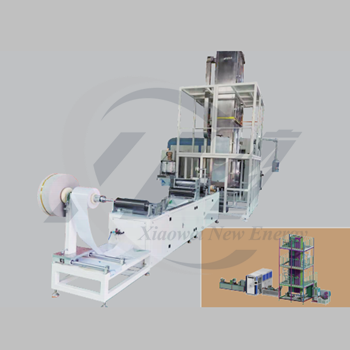

Products Description

- Double motor double reducer drive cardan shaft transmission, electronic control part using PLC and touch screen tension, pressure, speed online adjustment; The hydraulic pressure is pressurized by electric booster pump, and the servo motor drives the intermediate inclined iron to automatically adjust the gap.

- Two rolling up and down arrangement, “mouth” type cast steel arch overall strong, good stability, equipped with roll disassembly device.

Work process: Active servo unwinding → taping platform → unwinding tension detection → unwinding speed tracking swing roller → edge cutter → brush suction cartridge → magnetic iron removal → rolling (upper and lower rollers with scrapers) → unwinding speed tracking swing roller →unwinding tension detection → unwinding tape platform → active servo unwinding → Ultrasonic coil diameter detection

Technical Parameters

| Φ300 Roller Press/Calendering Machine(Lab Version) | |

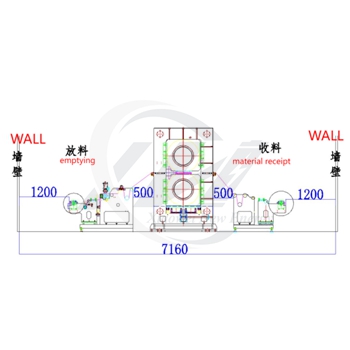

| Roll specification | Φ300x350mm 300 * 400(can be customized according to customer demand) |

| Machine speed | 2 ~ 8r m in |

| Power requirements | 380V/50Hz, power 7.5KW; |

| Material | 9cr3Mo series high alloy cold roll steel |

| Surface hardness | HRC66-68 |

| Quenching layer depth | 18 ~ 25mm |

| Roll diameter skip | ≤ ±0.001mm |

| Roller surface roughness | Ra≤0.4 |

| Maximum working pressure | 25Mpa |