Introduce

(Pre-Sealing) Vacuum Pouch Sealing Machine is used for vacuuming and hot-pressing pre-sealing of pouch cell batteries after they are filled with liquid and left to stand.

The electrolyte in the battery needs to be sealed under vacuum conditions to ensure the safety and stability of the battery. The lithium battery vacuum pouch sealing machine can effectively reduce the gas content during the packaging process and improve the quality and performance of the battery.

It can also improve production efficiency, reduce manual operations, and reduce costs.

About 3 devices for laboratory research on lithium battery pouch cell battery sealing.

- (top&side) pouch cell sealer machine;

- pre-sealer vacuum pouch sealing machine;

- final sealer machine for pouch cell.

More pouch cell lab research equiment video.

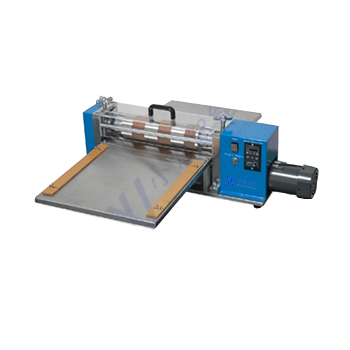

(pre-sealing) vacuum pouch sealing machine

Features

- The head is made of copper material, good heat transfer effect, save power consumption, improve work efficiency, energy saving than similar products;

- The pressure of the upper and lower head can be adjusted by the pressure regulator to achieve different technical parameters;

- The upper and lower head is driven by the cylinder through two linear guide sleeves, which accurately ensures the parallelism of the product after edge sealing;

- Through the perspective window, changes in the cavity can be observed while working;

- The cover cavity is driven by the cylinder, guided by the rotating guide sleeve, the up and down movement is lively, and the guidance is accurate to ensure the sealing requirements of the product;

- Can be applied to different specifications of product batteries, and the adjustment is simple and convenient;

- The main machine and control box split design, so that the machine can be placed in the glove box work, can also be placed on the assembly line work;

- Beautiful appearance, small size, light weight;

- PLC touch screen control, easy to understand operation;

Main Parameters

- Head length: 200mm;

- Edge width: 5mm; Can be customized according to requirements;

- Head temperature: normal temperature ~300℃, the temperature is adjustable;

- Temperature control accuracy: ±2℃

- Equipment weight: about 50Kg;

- Heat sealing time: 0 ~ 99 seconds adjustable;

- Vacuum degree: adjustable up to -98Kpa;

- Parallel clearance when the upper and lower heads are engaged: ≤0.02mm;

- Power supply: AC220V/50Hz;

- Air source: 5~7Kg/cm2 adjustable;

- Dimensions: Working section: L470xW485xK435mm;

- Control box: L420xW325xH225mm;