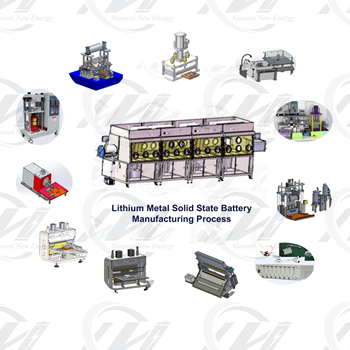

Lithium metal battery solid-state battery manufacturing process

Lithium metal batteries and SSD batteries are two different types of battery technologies, and their manufacturing processes are also different. The following is a brief manufacturing process for lithium metal batteries and SSD batteries:

Lithium metal battery manufacturing process:

- Electrode preparation: First prepare the electrode (usually an electrode) and electrode material (such as lithium metal);

- Continuous liquid preparation: Use a continuous liquid, which usually contains lithium salt and solvent;

- Build the battery: Place the completed battery and the tray (usually polymer) in the battery case in sequence, and then inject the sustaining fluid;

- Encapsulation: Seal the battery casing to ensure that the inside of the battery is isolated from the casing;

- Charge and discharge cycle test: Conduct charge and discharge cycle test on the battery to ensure its stable performance;

- Safety test: Conduct safety tests such as overcharge, over-discharge, and short circuit on the battery to ensure that the battery is safe and reliable;

- Packaging: Pack the qualified batteries and prepare them for sale or use;

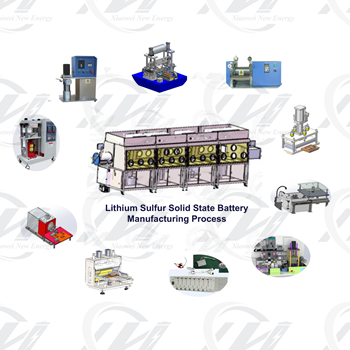

Solid-state battery manufacturing process:

- Electrode material preparation: Prepare solid electrolyte and electrode materials (such as lithium metal or lithium ion acceptor);

- Electrode coating: coating the electrode material on the surface of the solid electrolyte to form an electrode layer;

- Assemble the battery: Place the homomorphic electrolyte sheet coated with electrode material inside the battery case;

- Packaging: Seal the battery shell to ensure that the inside of the battery is isolated from the outside world;

- Charge and discharge cycle test: Conduct charge and discharge cycle test on the battery to ensure its stable performance;

- Safety test: Conduct safety tests such as overcharge, over-discharge, and short circuit on the battery to ensure that the battery is safe and reliable;

- Packaging: Pack the qualified batteries and prepare them for sale or use.

It should be noted that the manufacturing process of solid-state batteries is still evolving and may vary between different manufacturers and technology routes. In addition, the performance and safety testing standards of solid-state batteries are also more stringent to ensure their widespread application in future electric vehicles and portable electronic devices.