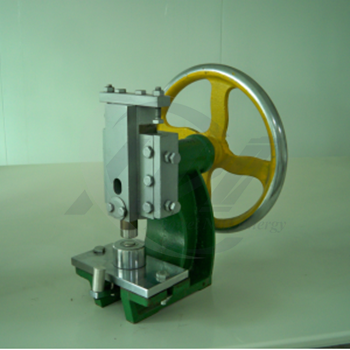

Products Description

Mainly used in laboratory battery materials research and development of sample production of batteries, capacitors scientific research and sealing, can also be used for factory low-batch trial production. Pneumatic method to save effort.

Technical Parameters

- Gas source: argon, nitrogen cylinders, or compressed air (Compressed air is not recommended in the glove box);

- Exhaust design: Specially designed exhaust port, through KF40 and other devices external gas consumption: a single sealing gas consumption of about 480ml;

- Sealing pressure: manual control valve, recommended pressure 0.4MPa;

- Sealing stroke: 30mm;

- Sealing mold: Standard CR20 series packaging mold, Other specifications can be selected or added;

- Removal mold: optional or additional CR16, CR20, CR24, CR30 and other specifications;

- Installation dimension: L220mm * W220mm * H420mm;

- Weight: 35Kg;

- It has the function of preventing short circuit of battery sealing;

- Structure material: high strength chromium steel, the surface is environmentally friendly electroplating and spraying Coating never rusts.

Product Feature

- The lower die adopts high-precision positioning ring limit to control the height of the battery package, so as to avoid the instability of the package pressure, which leads to the damage of the battery and sealing cup;

- The inner ring of the upper die sealing cup is equipped with a screw spring core mechanism, which ensures that the button battery can be pushed out forcefully by twisting the top screw in case the battery is stuck when it is sealed;

- Compressed air or inert cylinder two ways of gas supply, compressed gas exhaust external connection can prevent damage to the glove box atmosphere;

- Precision mold design ensures accurate and reliable sealing molding, solid steel structure design, stable and safe use;

- Small size, easy to operate, can be placed in the glove box (Ø360 transit bin) operation;

- Pure pneumatic operation, no need for electricity, easy to use.