Introduce

The NMP waste gas recovery and treatment system and waste heat recovery device of the coating machine recycle NMP waste gas, and the air is discharged up to standard after purification.

NMP recovery treatment achieves the goals of energy saving, consumption reduction, NMP treatment and gas purification of the air supply and exhaust system through heat recovery, dehumidification and filtration. Zhaohe NMP recycling system meets the requirements for temperature, cleanliness, NMP concentration and pressure in the oven during the coating and drying process during the lithium battery cathode production process.

more battery lab research video

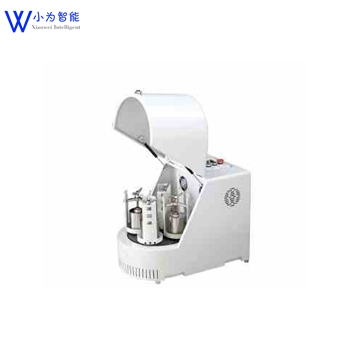

Two-Stage NMP processor

Features

- Used for the filtration treatment of the solvent in the exhaust gas produced in the drying process of the coating machine, water bath principle.

- Equipped with fan, active self-suction air intake, can be directly added to tap water for use, simple operation.

- Recovered solution electric pump discharge, explosion-proof design.

- Two-stage water bath treatment unit, good for NMP and dust recovery.

- Stainless steel full welded inner liner has good corrosion resistance and can be installed indoors and outdoors.

Main Parameters

- With work timing function

- Working mode: continuous working

- Processing capacity: 600m3/h

- Intake temperature: ≤150℃

- Recovery rate: 280%

- Recovered object: water-soluble solvent gas

- Processing object: gas

- Processing range: water-based solvent

- Contact material: SUS304 stainless steel

- Gas emission: external piping

- Vibration and shock: there is no obvious vibration source around

- Explosion-proof: the equipment itself explosion-proof treatment

- Voltage: single-phase AC220V

- Power: 1.5KW

- Size: L800×W500×H1800mm

- Weight: 300KG