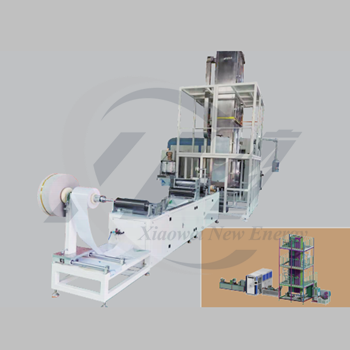

Products Description

The whole production process is fully automatic, and the production technology of nickel foam automatic correction and discharge, tape connection, tape storage device, nickel foam pre-pressing, roll pressing, powder vacuuming, slitter and cutting is carried out on the electrode strip of the battery.

Work process: Unwinding → automatic correction → pneumatic tape connection → pre-pressing of foam nickel tape thickness → taping lug → tape storage device → powder on dry powder →suction lug position → rolling → clean powder vacuuming → pole sheet buffering →step feeding → pole sheet forming cutting → belt flow receiving

Technical Parameters

| Ni-mh Positive Dry Process Production Line | |

| Power requirements | 380V/50Hz |

| Total power |

25KW |

| Mechanical transmission speed | 0.5m-7m /min(variable frequency adjustable) |

| Powder box | built-in four-brush, with adjustment motor (brush can be customized according to customer requirements) |

| Roller matching machine | Yujia standard all models are available (customer choice model) |

| Unwinding diameter | Φ1.2 m |

| Pole cutting accuracy | 0.05mm |

| Connecting cylinder | Φ120 * 50 |

| Pressure ear speed | 0.5-12m (adjustable) |

| Pressure ear range | 0.5-2 mm (adjustable) |