Introduce

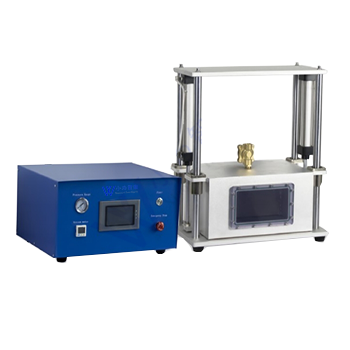

The semi-automatic aluminum laminated film forming machine is suitable for punching and forming aluminum-plastic film shells for pouch cell lithium batteries. Use a forming mold to punch out a shape that can hold the roll core on the aluminum plastic film while heating.

The equipment uses the principle of a boosted cylinder to achieve the pressure required for stamping, converting the smaller air source pressure into a larger liquid pressure output, thereby driving the mold to stamp the aluminum-plastic film shell.

aluminum laminated film for pouch cell case video.

Aluminum laminated film forming machine

Features

- Easy and fast to adjust the drawing depth;

- Easy and fast to replace mold;

- No crow’s feet and falling corners in and around the molded product;

- Four-guide column structure, sliding smoothly up and down with high precision;

- Use light curtain, double button operation and cover protection, safe to use;

- Compared with similar products, the same quality of aluminum-plastic film this product pulls Reach deeper and more stable;

- Easy to operate, safe and reliable, beautiful appearance, small size;

Main Parameters

- Applicable specifications: Max L200mm*W150mm (can be customized according to requirements) Punching depth Max6mm, related to the quality of tensile strength aluminum-plastic film;

- Booster cylinder: 3T, adjustable;

- Counting mode: counter display;

- Power supply: AC220V/50Hz;

- Power: 100W;

- Air source: 0.5MPa~0.7MPa;

- Weight: Approx. 180kg;

- Device size: L460xW320xH925mm;

- Mold/core roughness: 0.4;

- Upper and lower die flatness: 0.02mm;

- Core flatness: 0.02mm;