Products Description

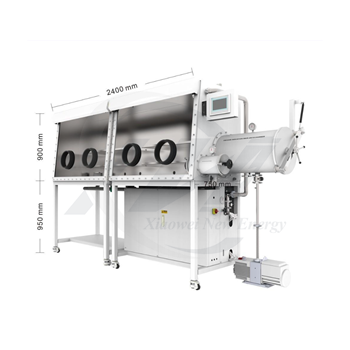

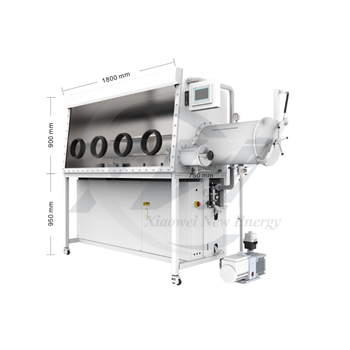

XW-GB-2000 Glove box is a high performance, high quality closed cycle working system that automatically absorbs water, oxygen molecules and purifies the working environment, providing an inert atmosphere of 1ppm O2 and H2O to meet your specific cleaning requirements. The system is an economical circulating purification system designed to meet the customer’s lab research and development.

The GB-2000 system consists of a closed housing, a transition chamber, a rotary vane vacuum pump and a circulating purification system with an integrated microcontroller operating panel.

Standard GB-2000 systems are equipped with an inert gas purification system with a set of purification columns (fully automatic and renewable) to purify and maintain the gas environment in the glove box.

Technical Parameters – Glove Box

| Glove Box | ||||||||

|---|---|---|---|---|---|---|---|---|

| Description Material |

Stainless steel 1.4301 (SUS type 304), thickness 3 mm Dimensions: 1200mm(L) x 750mm(W) x 900mm(H) |

|||||||

| volume | 0.8 m³ | |||||||

| Window |

Panel: 8 mm thick safety tempered glass or 10 mm thick polycarbonate (optional) Size: 1123mm(L) x 839mm(H) |

|||||||

|

Glove Opening |

Duralumin material or polyformaldehyde material (optional) Caliber 220 mm, O-ring seal |

|||||||

|

Gloves |

Material: butyl rubber Thickness: 0.4mm or 0.8mm(optional |

|||||||

| Filter | Outlet and inlet filters, filter <0.3μm illumination |

|||||||

| Lighting | LED lighting is located at the top of the front window | |||||||

| Gas Purification System | ||||||||

| Description |

Automatically removes H2O and O2; Single purification column system, automatic regeneration (optional GP200 double purification column); Closed gas circulation line. |

|||||||

| Voltage | AC 230 V / 50-60 Hz, 10 A or AC 115 V / 50-60 Hz, 20 A (optional) | |||||||

| Working Gas |

Working gas: N2, Ar, He (purity ≥99.999%) Regas: H2 accounts for 5%-10%, and the rest is working gas (purity ≥99.999%) |

|||||||

| Vacuum pump |

Specifications: Rotary vane vacuum pump, with oil mist filter, with gas ballast control; Flow rate: 12 m³/h (7 cfm), double substrate, vacuum < 2 x 10-3 mbar or dry pump (optional); |

|||||||

| Cyclic unit |

Oil-free high speed fan Air volume: 80 m³/h |

|||||||

| Control cabinet size | 600mm(L) x 800mm(D) x 870mm(H) | |||||||

| Transition module | ||||||||

| Large transition chamber |

|

|||||||

| Small transition chamber |

|

|||||||

| Analyzer | ||||||||

| Oxygen analyzer |

|

|||||||

| Water analyzer |

|

|||||||

| Other | ||||||||

| Solvent cleaning system |

Material: Stainless steel 1.4301 (SUS type 304), thickness 3 mm Internal dimensions: 220mm(Φ) x 450mm(H) High quality activated carbon |

|||||||

| Icebox |

Independent control system, integrated in the side panel of the box, temperature -35℃, volume 18L or 32L optional; Main body 304 stainless steel plate, 5 layers of variable insulation; R404 Environment-friendly refrigerant, originally imported. |

|||||||

| Heating cabin | Large transition configuration heating system, temperature is 200℃, temperature control ±1℃ | |||||||

| Warranty period | One year warranty, lifetime maintenance | |||||||

| Product certification | ISO9001 certification, CE certification, UL certification | |||||||