Products Description

- Heating Roller Press Machine is mainly used for continuous roll production of lithium-ion battery electrode sheet materials, rolling the battery electrode sheet to the density and thickness required by the process, and the coil is harvested by the winding mechanism;

- The equipment is cast 45# steel frame, large slider structure, bearing force is large, deformation is small, rolling force is large, rolling speed is high;

- It has the function of cutting edge and roll surface cleaning mechanism;

- With correction tension control winding, winding;

- With a pole plate buffer device;

- The pneumatic pressurization system controls the lifting of the cylinder through the man-machine interface to drive the lifting of the roller;

- Constant pressure automatic control, adjust the roll oil pressure through the man-machine interface;

- Man-machine interface input adjustment to change the oil pressure to roll gap.

Work process: Unwinding → feeding platform → correction system → tension control system → edge cutting device → buffer device → heating device → roller press → roller erasing device (negative electrode only) → buffer device → tension control system → correction system → feeding platform → winding

Technical Parameters

| Incoming material parameters | |

| Applicable material system | Cathode: lithium iron phosphate, lithium cobalt, lithium manganate and ternary materials

Anode: graphite, silicon carbon, etc |

| Incoming material coating method | Transverse intermittent, continuous multiple zebra coating, continuous coating, etc |

|

Incoming specification |

1) Substrate thickness: aluminum foil 10 ~ 35μm, copper foil 6 ~ 25μm;

2) Pole thickness: 100-300μm; 3) Material coil diameter: Max.φ500mm; 4) Roll weight: Max.300kg; 5) Pole thickness error: ≤±2μm; Barrel specification: Inner diameter 3 inches, length ≤650mm. |

|

Output product specification |

1) Thickness error of electrode plate after pressure: ≤±2μm (remove abnormal areas of head and tail and edge);

2) Material coil diameter: Max.φ500mm; 3) Roll weight: Max.300kg; 4)Winding edge deviation: ≤±0.4mm. |

| Equipment technical index | |

| Roll size | Φ400mm×450mm (roll surface diameter × roll surface width) Effective roll width 420mm |

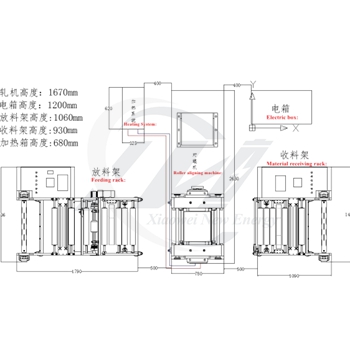

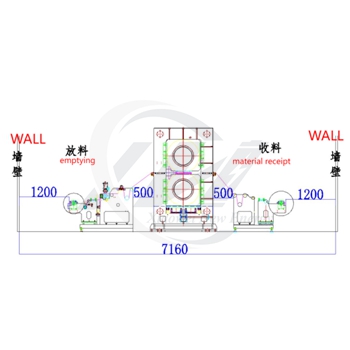

| Line placement dimension | Approx. Length 4660mm× width 2680mm× height 1800mm (excluding roll removal reserve) |

| Size of roller press | Approx. Length 2680mm x width 780mm x height 1800mm |

| Device color | Supplier standard color or specified color. |

| Weight of a single device | The total weight of the production line: about 5T, the weight of the roller press is about 4T |

| Load-bearing requirement | The roller part requires the ground load to be ≥3t/㎡, and the backing plate is placed at the bottom of the equipment |

| Air pressure | 0.5Mpa ~ 0.7Mpa (oil and water removal), flow rate :0.04M3/min |

| Environmental requirement | Temperature range 0 to +45 ° C Relative humidity: ≤50% |

| Power requirements | 380V, 50Hz three-phase five-wire system |

| Whole line power | Power 10KW |

| Rolling production speed | Max.12m/min |

| Pressure between two rolls | Max.200T |

| Pass rate | ≥99% (excluding bad incoming materials, power supply, gas supply and other influencing factors) |

| Equipment failure rate | ≤1% (Only faults caused by equipment are calculated) |

| Equipment configuration | |

| Unwinding mechanism | A set |

| Roller press | A set |

| Winding mechanism | A set |

| Control system | A set |

| Heating device | A set |

Equipment structure details

Winding mechanism:

- Function overview: The unwinding machine is used to support the coil to be rolled and transport it to the mill for rolling;

- Structural form: Overall 45# side panel structure, thickness 30mm, chrome plated surface;

- Loading and unloading method: Manual loading and unloading;

- Unwinding support: Inflatable 3-inch inflatable shaft, equipped with inflatable gun, both ends of the safety clamp support;

- Overroll: Aluminum alloy rolled, surface oxidation treatment HV700;

- Receiving platform:

- Double pressure rod, single scribing groove, manual feeding platform;

- Function: It is used for splicing when the pole sheet is broken or replaced during the rolling process to reduce the waste of the pole sheet;

- Composition: including splice plate, pressure rod, cylinder, guide roller and other parts of the unwinding machine device as one;

- Control: The cylinder is controlled by the electromagnetic pneumatic valve to tighten and loosen the pole plate.

- Deviation correction system: Infrared photoelectric correction, controller accuracy ≤± 0.1mm;

- Tension control system:

- Tension adjustment range: 0 ~ 200N;

- Tension control accuracy: ≤±5N (stable operation of the equipment).

- Trimming device:

- Function: It is used to cut both sides of the electrode coil before rolling, reduce the pole sheet fold caused by inconsistent roll elongation, and reduce the scrap rate caused by the pole fragment;

- Cutting tool form: upper cutting blade manual feed, knife, left and right cutting knife control;

- Cutting width: 300 mm ~ 420mm, can be implemented single, double cutting;

- Cutter speed (max) : 50 r/min;

- Buffer device:

- Function: reduce the jitter of the pole sheet in the rolling process to prevent broken tape;

- Composition: fixed guide roller, rolling guide roller, linear guide rail, fixed support, including front and rear vibration reduction two parts;

- Principle: The pole plate through the rolling guide roller, to reduce the pole plate shake, to prevent the pole fragment belt purpose.

- Driving mode: Passive unwinding;

- Control system: Set the function operation button.

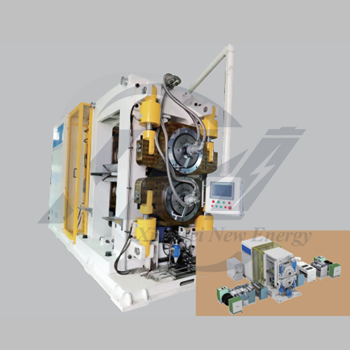

Roller press:

- Feature:

- Make the pole sheet under the rolling of the roll, make the pole sheet reach the appropriate density, and reach the pole sheet thickness requirements according to the coating thickness.

- The equipment adopts the ball screw wedge iron gap adjustment structure to adjust the roll gap, and the linear speed is adjusted by the frequency converter to achieve stepless speed regulation.

- layout: “Mouth” casting arch, the whole base, two rollers up and down horizontal arrangement;

- Machine casing:Cold-rolled sheet, 1.5mm or more;

- Bearing block: 45# cast steel with adjustable support block clearance device;

- Main bearing: Mill bearing;

- Bearing lubrication: High temperature lubricating grease;

- roll:

- Roll specification (roll surface diameter * roll surface width) : 400*450mm

- Effective width of roll surface: 420mm

- Roll material: 9Cr3Mo (Cr3 series high alloy cold roll steel)

- Roller body quenching hardness: HRC66-68, the rest of the quenching treatment HS40-45

- Roll tempering: HB280-300

- Quenching layer depth: 22 ~ 26mm

- Special treatment of roller surface: hard chromium plating on the surface, chromium plating thickness ≥0.18mm

- Roll diameter jump: ≤±0.001mm (detected on the grinding machine)

- Roller surface roughness: Ra≤0.02

- Roll cylindricity ≤±0.001mm

- Overall no-load diameter runout: ≤±0.002mm

- Diameter difference of upper and lower rollers: ≤0.02mm

- Roll body and shaft neck ultrasonic inspection, inspection standard GB-T13314-2008, grade A or above qualified

- Transmission mode:The upper and lower rollers of universal coupling are respectively driven;

- Roll drive: Double motor + cycloidal pinwheel reducer drives roll operation

- Main motor power: 8KW (2 *4KW 380V 50Hz);

- Heating device: The oil temperature machine is heated before rolling, and the temperature is adjustable from 50℃ to 150℃.

- Hydraulic cylinder: Cylinder diameter φ200mm*2 strokes 10mm;

- Two roll line pressure: 0.45 ~ 4.5t/cm;

- Roll gap adjustment mode: Middle wedge stepper motor to adjust the hydraulic constant pressure pressing;

- Roll gap adjustment: Adjustment range 0 ~ 3mm, online adjustment (no pressure relief), roll gap adjustment accuracy 0.001mm, displayed on the touch screen.

- Job pressure:

- Pressure mode: the main hydraulic cylinder is placed under the top

- Hydraulic system: single constant pressure hydraulic station

- Maximum pressure of hydraulic system: 50MPa

- Safety protection: Feed handguard, emergency stop button

- Roll surface cleaning: A depth adjustable blade adjustment device is adopted, the blade is of a knife type structure, and the scraper is close to the roll surface to remove the roller adhesive, and there is a collection box, and the blade is cleaned in two sets of upper and lower rollers;

- Roller wiping device (negative electrode only):

- 1) The role of the roller rub is to wipe the roller surface of the sticky roll dust, the rolling process often appears in the graphite negative electrode sheet in the rolling process of the material drop phenomenon, the powder is basically attached to the roller above the roller press, such as the result of the wipe is not timely, the adhesion of the powder particles will adhere to the next negative surface, damage the electrode sheet caused by the battery in the charge and discharge process safety problems.

- 2) The roller wiping device includes a motor drive device, a left and right swing plate and a slide mechanism connecting the two, and the roller wiping device includes a wiping device that is matched with the roller face of the roller press and a control device that controls the distance between the wiping device and the roller face of the roller press, controls the reciprocating motion of the roller wiping device, and controls the wiping device by adjusting the cylinder The distance between the roller device and the roller surface achieves the effect of removing powder.

- 3) Quantity: 2 sets (1 set for each upper and lower roller)

- 4) Roller width: same as the width of the roller surface

- Use requirements: The roller cloth must be replaced regularly in strict accordance with the process regulations (the replacement cycle of the roller cloth is determined according to the field use situation and the degree of cleaning of the roller surface).

Winder

- Function overview: The unwinding machine is used to support the rolled coil and harvest it;

- Structural form: Overall 45# side panel structure, thickness 30mm, chrome plated surface;

- Loading and unloading method: Manual loading and unloading;

- Winding support: Inflatable 3-inch inflatable shaft with inflatable gun, supported at both ends

- overroll: Aluminum alloy rolled, surface oxidation treatment HV700;

- Receiving platform:

- Double pressure rod, single cutting groove, manual feeding platform;

- Function: It is used for splicing when the pole sheet is broken or replaced during the rolling process to reduce the waste of the pole sheet;

- Composition: including splice plate, pressure rod, cylinder, guide roller and other parts of the unwinding machine device as one;

- Control: The cylinder is controlled by the electromagnetic pneumatic valve to tighten and loosen the pole plate;

- Deviation correction system: Infrared photoelectric correction, controller accuracy ≤±0.2mm

- Tension control system:

- Tension adjustment range: 0 ~ 200N;

- Tension control accuracy: ≤±5N (stable operation of the equipment).

- Buffer device:

- Function: reduce the jitter of the pole sheet in the rolling process to prevent broken tape

- Composition: fixed guide roller, rolling guide roller, linear guide rail, fixed support, including front and back vibration reduction two parts;

- Principle: The pole plate can reduce the flutter of the pole plate and prevent the pole fragment belt by rolling the guide roller;

- Driving mode: The motor drives the inflatable shaft to realize winding;

- Control system: Set the function operation button.

Control system:

- The system runs by PLC bus control, touch screen and button operation mode;

- It can realize the digital setting of equipment running speed, pressure, roll gap and so on;

- It has the function of setting the power password and device administrator password;

- Manual, automatic, emergency stop button; The winding mechanism, roll press and unwinding mechanism can be operated by pushing buttons;

- When the device fails or starts, the device is equipped with a three-color warning light, and the touch screen will display the corresponding correction screen;

- There are emergency stop and stop buttons in the main machine and the winding part, which are integrated with the roller press.

Configuration of main equipment components:

| roll | Xingtai (provide inspection report) |

| Touch screen | Kunlun pass state |

| Roll gap adjustment stepper motor | Germecon |

| module | Mitsubishi |

| PLC | Mitsubishi |

| Frequency changer | Huichuan/Continental Europe |

| Hydraulic boost system | ENERPAC USA |

| Pendulum gear reducer | Guo MAO/O Tai |

| Deviation correcting device | Yunfan/Dongdeng |

| Bearing: P5 high precision roll bearing | Wafangdian |

| Cylinder, hand pull valve, solenoid valve | Airtac |