Products Description

The coated lithium battery electrodes are rolled and must be cutting into large pieces for rolling and cut into small pieces for welding.

In the battery production process, the lithium battery electrodes after continuous coating are rolled into rolls, which need to be cut into electrode sheets of specific sizes by a slitting machine, and then rolled and cut into small pieces for welding.

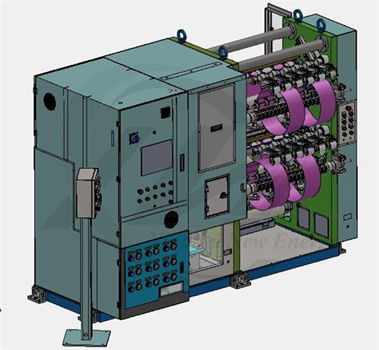

Xiaowei’s fully automatic high-speed slitting machine solves the slitting process of battery production

- This equipment is designed for continuous slitting and continuous winding of cathode and anode electrode sheets after intermittent coating in lithium-ion battery production.

- The unwinding adopts air expansion shaft, constant tension control by magnetic powder brake and photoelectric correction control.

- The winding uses two special slip shafts to completely ensure that the winding tension of each belt after slitting is consistent, each belt is completely synchronized, and continuous slitting will not cause belt breakage. The winding tension is automatically tracked and detected and adjusted on the touch screen, so the tension is uniform and stable. The winding tension, slitting speed and slip shaft pressure are all set on the touch screen.

- The slitting knife holder is installed on the trolley, and knife holders with different slitting widths can be prepared; when slitting is required, push the knife holder to the slitting machine and perform slitting after mechanical positioning (the positioning process is very simple) . It avoids the trouble caused by frequently adjusting the tool when slitting different widths, and also increases the service life of the tool. It is suitable for large-volume and small-volume battery production.

- The active traction is controlled by servo motor, and the winding is controlled by Mitsubishi frequency converter and PLC program control.

- The slitting adopts blade roller shearing method, which is especially suitable for slitting pole pieces after intermittent coating.

- The blade roller shear tool adopts advanced technology, which is the leading technology in the china. There is no burr on the edge of the pole piece after slitting.

- Especially for the slitting of aluminum foil and uranium foil, which are the base materials of the pole pieces, there are no ripples or burrs.

Technical Parameters

| Automatic Slitting Cutting Machine For Battery Electrode Cutting Process | |

| Slitting Cutting speed | 0-50m (stepless speed adjustment) |

| Slitting Cutting width |

|

| Slitting process accuracy | The dimensional tolerance of the slitting width is ±0.05mm, the edge burr size after slitting is ≤5um, and the edge serpentine offset is less than ±0.05mm. |

| Unwinding and correction accuracy | ±0 1mm |

| Rewinding accuracy | ±05mm |

| Cutting thickness | 0.05-0.3mm |

| Unwinding tension | 0-100Nm; Rewinding tension: 0-100Nm |

| Air pressure | 0.5Mpa |

| Equipment power | 6 KW |

Equiment Display