Products Description

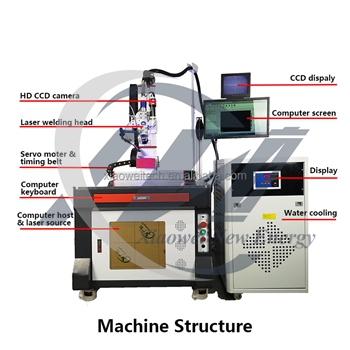

In the prismatic cell battery pilot production line, xiaowei uses laser welding (which can be divided into galvanometer + 3-axis) to weld the prismatic battery cover. Since the prismatic cell battery cover structure is relatively complex, it will be more difficult to use 3-axis laser welding. More, more versatile, the welding track can be monitored in real time during welding, and the welding track is controlled by G code programming.

Technical Parameters

| Prismatic Cell Injection Machine | |

| Equipment size | L1600mm*W1550mm*H1700mm |

| Power Supply | Three-phase AC350V±10%, frequency 50Hz, Power: 5KW |

| Weight | About 600kg |

Function Description:

1. Use a three-axis manipulator equipped with a coaxial CCD laser welding head;

2. The laser is a 2KW fiber continuous laser;

3. Suitable for welding of pole lug and end cover, spot welding and fixation of end cover, seal welding of end cover, etc. Corresponding fixtures are required and can be compatible at the same time;

4. The weld track can be monitored in real time during welding;

5. The welding trajectory is controlled by G code programming.