Products Description

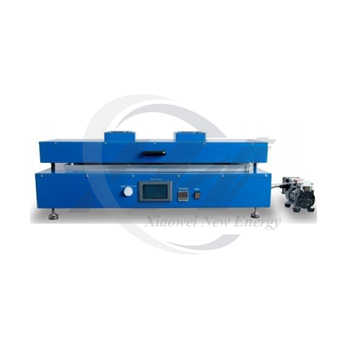

The double temperature zone transfer coater is a three-roll transfer coater that can be applied continuously and intermittently for surface coating of various substrates. Especially used in the lithium-ion cell industry, the equipment is convenient for researchers to use, while meeting the requirements of coating accuracy and consistency is equivalent to production design, excellent drying effect, ias the ideal choice for lithium-ion batteries, supercapacitors, nickel batteries and other secondary battery research and development and pilot testing.

Technical Parameters

- Double temperature zone drying control, 1 m/section, a total of 2 sections (customizable length) double zone independent temperature control, using analog signal to control power heating;

- High precision ±0.3℃ heating system, long life;

- Drying temperature: room temperature ~150° C adjustable;

- Drying unit: standard hot air drying;

- Coating method: intermittent coating, continuous coating;

- Guide rod spoke width: 330mm;

- Coating width: Max300mm;

- Mechanical speed: 200 ~ 1500mm/min;

- Coating thickness: depending on the stock, 40~300um;

- Winding diameter (Max):Ø250mm;

- Winding accuracy: + / – 0.5 mm

- Tension control: Max60N (adjustable);

- Indicator display accuracy: 1um;

- Compressed air: 0.5~0.7Mpa;

- Power supply: AC220V 50Hz;

- Maximum power: 10KW;

- Dimensions: L2800xW1200xH1200mm;

- Weight: About 1200kg.

Product Feature

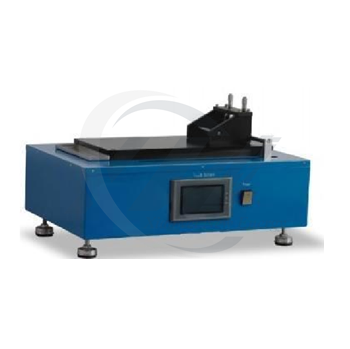

- Divided into different temperature zone drying, better effect;

- Can be freely switched to achieve continuous and intermittent coating;

- Substrate tension control, walking stability, equipped with deviation correction device;

- Hot air oven, upper and lower double-sided blowing, drying effect is high quality;

- Three-roll transfer coating, with a wide coating window;

- Comma scraper metering, with precision adjustment mechanism, to obtain high coating accuracy;

- Using analog signal to control power heating, heating system accuracy is high ± 0.3℃, long life;

- PLC control, touch screen operation, easy to use;

- Optional solvent recovery treatment device.