Introduce

Slitting machines are often used together with cutting machines to cut electrode sheets of any size.

The slitting machine is used for longitudinal slitting of positive and negative electrode sheets after coating of nickel metal hydride, nickel cadmium, lithium ion and other batteries. The slice edges are neat, burr-free, high dimensional accuracy, and no powder removal. It is an important equipment in the processing of battery electrode sheets.

Slitting machines in large-scale battery production situations.

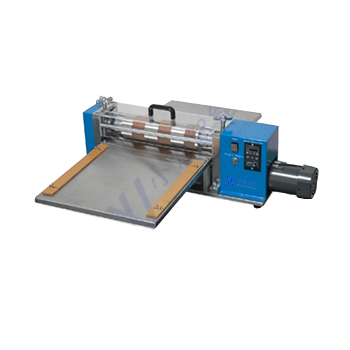

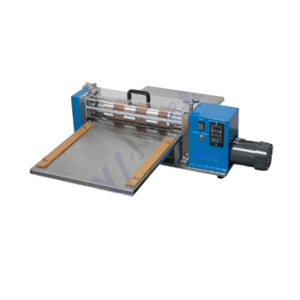

Laboratory slitting machine

Features

- Adjustable guide for feed positioning;

- Electric rolling scuttling method;

- The mesh can be adjusted;

- Upper and lower blades at the same speed, synchronous transmission;

- The hob is equipped with plexiglass protection device, safe operation;

- Open hob fixed mode, easy hob disassembly;

- High cutting precision, reliable work;

Main Parameters

- Cutter type: upper and lower round knife to cut;

- Cutter width: 20 ~ 300mm;

- Cutting thickness: 80-300μm The burr condition of the battery electrode slice is less than 25μm;

- Cutter diameter: 85mm;

- Slitting speed: Max4m/min, adjustable speed;

- Power supply: AC220V/50Hz;

- Power: 200W;

- Dimensions: L850×W920×H400(mm);

- Weight: about 60KG;