Products Description

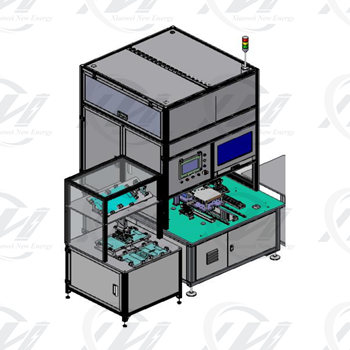

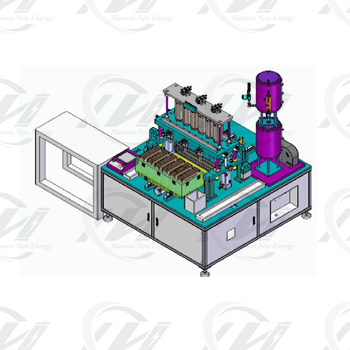

The equipment is a semi-automatic Mylar film wrapping machine. The bottom support sheet and Mylar film are manually loaded, and the equipment automatically completes the hot melting. The material is manually transferred to the cover hot-melt station, and the battery core is manually loaded. The equipment automatically completes the bending and holding of the large surface and side, and the equipment automatically completes the hot-melting of the top cover and Mylar. Finally, the material is cut and glued manually.

It is mainly used for the Mylar film machine for wrapping square batteries in the assembly section.

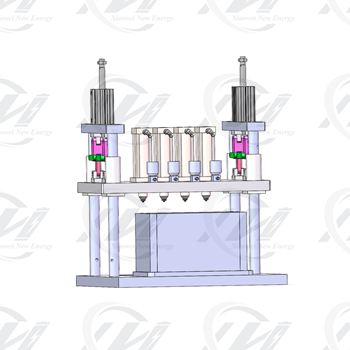

Complete the hot melting of Mylar film and bottom support sheet, Mylar film wrapping and hot melting of Mylar film and top cover bracket

Technical Parameters

| Overall dimensions | about 1300*1700*2400mm |

| Compressed air | ≥0.6MPa 20L/min (prepared by user) |

| Working method | Manual picking and placing of materials |

| Equipment power supply | AC 380V, 4KW |

| Heat sealing temperature | 150~300℃, adjustable |

| Heat sealing time | 1.5~4s, adjustable |

| Centering degree between the bottom support piece and Mylar | ±0.3 mm |

| The distance tolerance between the upper edge of the protective film and the bottom surface of the cover | ±0.5mm |

| Hot melt detection accuracy | 0.3mm |

| Equipment production capacity | 1PPM (depending on workers’ operating proficiency) |