Introduction – Film Coating Machine

Automatic film coating machine is widely used in various high temperature film research, such as ceramic film, crystal film, battery material film, special nano film.

The development of science and technology that can adapt to film formation under high temperature conditions in the future.

The coating process is a process based on the study of the physical properties of fluids. One or more layers of liquid are coated on a substrate. The substrate is usually a flexible film or lining paper, and then t he applied liquid coating is passed through an oven. Drying or curing methods form a layer of film with special functions.

Xiaowei provides coating machines with multiple functions: standard flat plate type, transfer type coating machine, extrusion type coating machine, which can be customized according to battery size.

In the battery production process, the coating machine uses a large roller coating machine.

More Laboratory Research Equiment

XIAOWEI Film Coating Mahcine Video: For reference only, the actual style is consistent with the quotation.

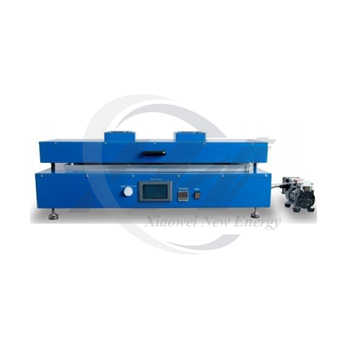

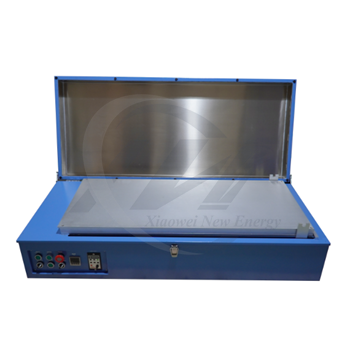

Automatic film coating dryer machine

Features

- The coating speed is adjustable in the range of 0 ~ 100mm/ s;

- Drying system with digital display temperature control;

- In 10 ~ 300mm, precisely adjust the stroke through the HIM screen;

- Vacuum aluminum tray for quick placement or removal of substrate;

- With adjustable film applicator;

Main Parameters

- Coating speed: 0~100mm/second;

- Maximum stroke: 300mm;

- Vacuum panel: aluminum flat plate with vacuum;

- Vacuum panel size: L365mm×W200mm×H30mm;

- Adjustable range of scraper: 0.01-3.5mm;

- Equipped with heating drying system;

- Power supply: 220V/50Hz;

- Weight: 55KG;

- Overall dimensions: 500mm(L)×310mm(W)×330mm(H);

- Optional micron-level 50~150mm wide film applicator.