Introduce

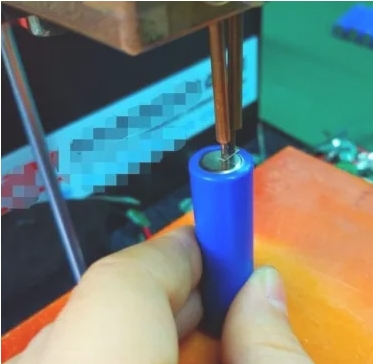

Battery welding machine is used for the welding of the negative shell and the electrode, the cylindrical battery (single pin welding Cylindrical cell bottom). Using automatic battery spot welding machine.

battery cell welding machine(Cylindrical cell bottom welding), The currently widely popular AC pulse spot welding machine is controlled by a microcomputer and its performance is more stable and reliable.

It is designed based on the current international production of high-end nickel-cadmium, nickel-metal hydride, and lithium batteries.

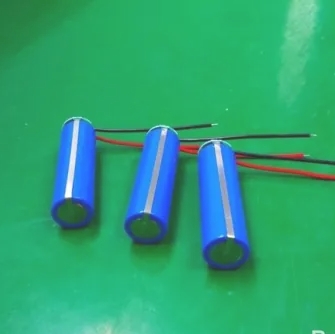

The battery welding machine can not only be used for welding cylindrical battery cores, but can also be used for link welding of cylindrical battery packs. Ultrasonic battery welding is also used in battery welding for cylindrical battery cap welding.

Cylindrical Cell Battery Welding Process:

Cylindrical Cell Battery Pack Welding:

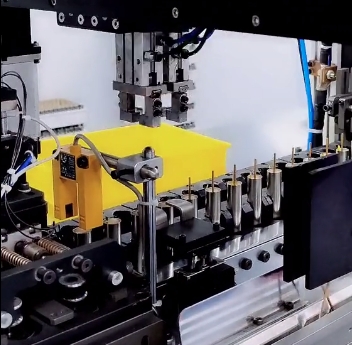

Battery spot welding machine in fully automatic cylindrical battery production video.

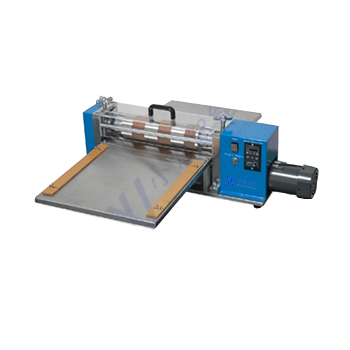

Cylindrical battery welding machine(Single Pin)

Features

- Stable welding current, uniform solder joint size, beautiful solder joint, spark Small, no blackness;

- Completely overcome the phenomenon of low pressure and water discharge after spot welding of lithium batteries;

- The ideal equipment for assembling batteries;

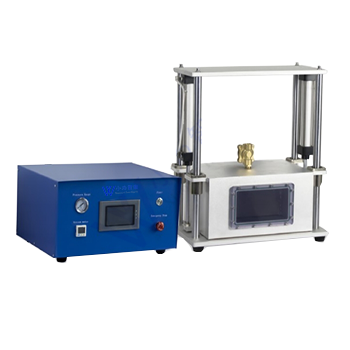

- Microcomputer control, can achieve single pulse, double pulse and multi-pulse welding;

- All parameters are set digitally, so the parameter adjustment is intuitive and accurate;

- The needle pressure is independently adjusted, and the adjustment is convenient to ensure that the welding pressure is stable and reliable;

- Accurate alignment welding, suitable for small cap cell welding, high yield;

Main Parameters

- Maximum output power: 10KVA;

- Welding current: 00 ~ 99A;

- Power supply: AC220V±10%50~60Hz;

- Input air pressure: 0.5 ~ 0.7MPa;

- Range of application: Applicable to a variety of welding pieces 0.03mm ~ 0.25mm;

- Weight: 45Kg;

- Size: L400×W560×H400mm;