Products Description

The Planetary Mixer Machine is one of the important equipment for new energy battery production.

Xiaowei provides 5L-3000L vacuum mixing equipment for the battery production process.

The planetary mixer is a mixing equipment that integrates planetary mixing and strong dispersion, with high production efficiency. When working, the mixing device rotates and rotates, and can be mixed or dispersed at low speed alone, or mixed and dispersed at the same time, causing the material to make complex movements and be subject to strong shearing and kneading.

The equipment adopts a unique sealing design and can be pressurized or evacuated during the production process.

Technical Parameters

|

Battery Production-Planetary Mixer Machine

|

|||||||

|

Model |

300L

|

500L

|

600L

|

1000L

|

1200L

|

2000L

|

3000L

|

|

Tank working Capacity/L

|

300L

|

500L

|

600L

|

1000L

|

1200L

|

2000L

|

3000L

|

|

Tank Design Size/L

|

368L

|

670L

|

807L

|

1327L

|

1846L

|

2300L

|

3400L

|

|

Tank Size/mm

|

850*650

|

1000*850

|

1100*850

|

1300*1000

|

1400*1200

|

1500*1300

|

1700*1500

|

|

Revolution Motor/Kw

|

22

|

37

|

45

|

55

|

75

|

90

|

0-9

|

|

Revolution Speed/rpm

|

0-26

|

0-22

|

0-22

|

0-20

|

0-15

|

0-13

|

0-24

|

|

Mix Speed/rpm

|

0-39

|

0-35

|

0-35

|

0-36

|

0-35

|

0-35

|

0-24

|

|

Disperse Motom/Kw

|

37

|

45

|

55

|

75

|

90

|

110

|

132

|

|

Disperse Speed/rpm

|

0-2200

|

0-2000

|

0-2000

|

0-1800

|

0-1500

|

0-1500

|

0-1000

|

|

Disperse plate linear Velocity(m/s)

|

0-23

|

||||||

|

Suttle/Kg

|

770

|

10300

|

11000

|

13500

|

16800

|

19500

|

23500

|

|

Measurement/mm (L*W*H)

|

3200*1600*3200

|

3600*1950*3900

|

3800*1700*4200

|

4300*1950*5000

|

4320*2100*4530

|

4430*2050*4950

|

4660*2280*5200

|

Main Features:

1. High line speed: The line speed can reach to 25m/s, shorten the dispersing time. The particle size of battery slurry is small and high uniformity, solve the problem of polymerization;

2. It adopts SKF Sweden import angular contact ball bearing, which can bear higher rotating speed, large increase the mixing speed and using life( The using life is more than 3 years under 21m/s and continuous 24hr working);

3. 0-0 assembling: precision assemble, the process tolerance of core parts is less than 30um, the running is more stable , the noisy outside I m rang is lower than 70 db(A);

4. High tightness, no air leakiness and oil leakiness: 2 sets of mechanical seal plus soft.hard seals etc. to keep the non load vacuum keeps above -0.095 in 24 hours, ensure that no air leakiness and oil leakiness during the mixing

5. The gap between tank and paddles, paddles to paddles, paddles to tank wall, paddles to tank bottom is less than 3-5mm;

6. Large torsion output: precision casting mixing paddles SS316 stainless steel (adopts special steel for machines bigger than 650L, the material can restore itself there is micro deformation.

Application

| Material viscosity | ≤ 1,000,000 cps |

| Production capacity | 2-3000L (working volume) |

| Application industry |

It is suitable for dispersing and mixing materials in high viscosity slurry, like Engineering Adhesives, New Energy, Electric Slurry Paste, Chemical Paste. |

| Applicable materials | All kinds of paste with viscosity less than 1,000,000 cps, solid content under 90%, such as lithium battery paste, solder paste, ceramic paste, silicone ink, sealant, structural adhesive, ointment, Composite filling material, Phase Change Material, Dental Paste, etc. |

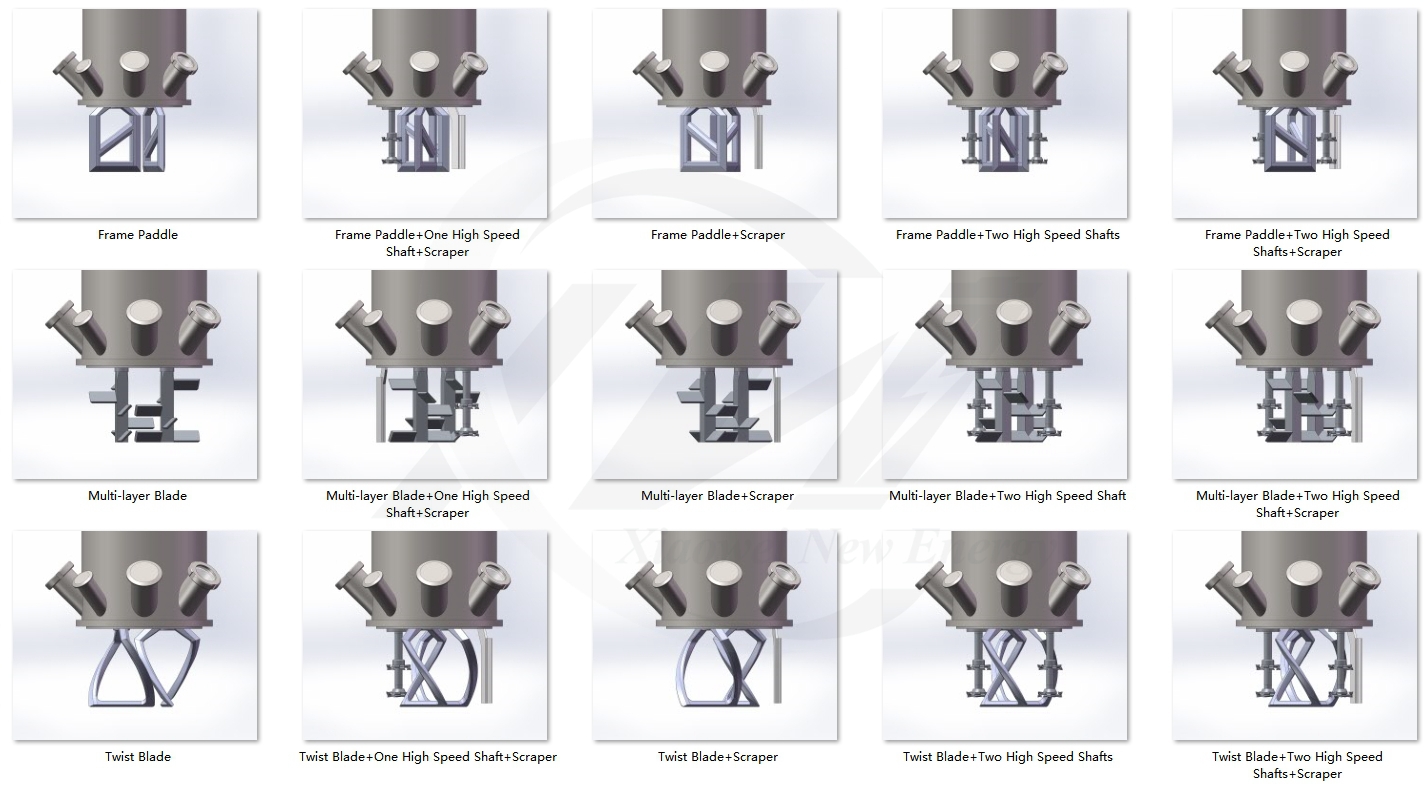

| Feature | Various types of blades can be selected according to the viscosity and characteristics of the material; It is equipped with pressing equipment for discharging and can be equipped with vacuum systems and heating systems. |

Display