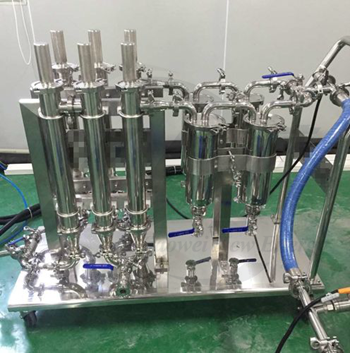

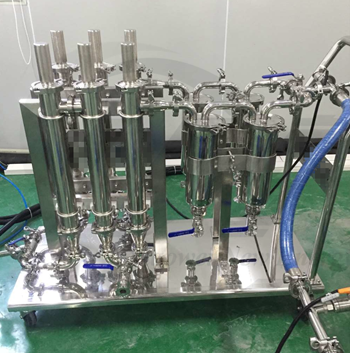

Products Description

The battery slurry iron removal filtration device is a lithium ion slurry iron removal and filtration treatment equipment. It is used to optimize the slurry treatment after the cathode and anode electrode slurries of lithium ion batteries are batched and before coating. The equipment is equipped with iron removal, vacuum filtration, and slurry transfer. Function.

Xiaowei provides static and dynamic filtration system solutions for battery slurry during the battery production process.

Technical Parameters

| Battery Slurry Static Magnetic Mesh Filter(Basic parameters) | |

| diaphragm pump | 1 set, specification 2.4m3/H, lift: 50 meters, suction lift: 7 meters, diameter: 1 inch, Skyli diaphragm pump |

| Magnet and mesh filters | Magnetic rod specification: Φ25×300, magnetic strength: 12000GS/piece, 3 magnetic rods/single pass;2 mesh filters (dual channels, with pressure detection and automatic overpressure alarm). |

| Pipes, bases and pipe connections | The base is equipped with 4 casters, 1 anti-corrosion mild steel wire, DN16, and there are no dead ends in the discharge pipe, pipelines and equipment interfaces. |

| Control System | 1 liquid level sensor, 1 control box, 1 doublet, and a set of flow controller; |

| Cart | One cart, diaphragm pump and filter are fixed on the cart and can be moved or fixed. |

Battery Slurry Static Filtration Features

- Double filter channel configuration (1 set for use and 1 set for backup), suitable for continuous supply of slurry; the two sets of filter channels can be switched freely;

- Used for slurry transportation from the transfer tank to the coating machine and liquid level control (with functions of iron removal and impurity filtering);

- The system includes:

- diaphragm pump;

- Dual-channel magnet filtration: Magnetic rod, strong magnetism, about 30% higher than similar products, super long life, magnetic force only decays by 1% in 10 years;

- Dual-channel mesh filtration: the positive electrode uses a 100-150 mesh filter, and the negative electrode uses a 100-150 mesh filter, used in parallel, with a single mesh filter area ≥ 3000cm2. Using a self-designed wedge-shaped mesh filter;

- The pipeline connected to the transfer tank can realize automatic control.

- Dual-channel filter and controller integrated;

- Discharging method: use bottom-up deletion to eliminate material waste.

Battery slurry dynamic filter

Dynamic filtration iron removal and feeding system

This system is used for automatic supply of slurry during the coating process of lithium-ion battery pole pieces. It can be configured individually or in combination, which can ensure the isolation of the slurry from the outside world, save labor, and prevent artificial contamination of the slurry.

The core technology of the dynamic scraper filter system lies in its filter screen and scraper assembly.

Each mesh section of the wedge-shaped filter screen is triangular, and the outer wall of the filter screen is smooth, which facilitates the scraper to scrape off impurities attached to it. The outside of the filter screen is an inverted triangle opening. Particles smaller than the filtration accuracy requirements will not get stuck on the filter screen, so that the filtration is always in good working condition. In addition, when in negative electrode filtration, a punching filter can be used to effectively intercept negative electrode fibers.

When the scraper scrapes across the surface of the filter, the blockage on the surface of the filter is smoothly scraped off, keeping the filter open. The large particles scraped off the filter surface by the scraper enter the waste chamber for easy discharge.

| Battery Slurry Dynamic Filtration System | |

| One diaphragm pump (L325 type) | ● Pump body material: 316SST; ● Diaphragm material: polytetrafluoroethylene; ● Maximum flow rate (water): 61-100 L/min; |

| 2 magnetic filter barrels | 7 magnetic rods/single barrel, 600cm2/single barrel, magnetic rod specification Φ20×125, magnetic strength 10000GS/rod; |

| 1 mesh filter bucket | Stainless steel mesh filter element, area 800cm2/single barrel, filter mesh number: the number of positive and negative filter meshes is selected by the customer; |

| Pipes, bases and connectors | 1 base with four casters (2 of which are universal); 1 25×1.5m chemical pipe; DN16 chemical pipe discharge pipe 3m;Integrated skid-mounted device with integrated bottom pulley for easy cleaning |

| Control system (1 control box) | ● 1 photoelectric sensor for coating machine material level control; ● 1 electrical contact pressure gauge for mesh filter impurity content control; ● 1 photoelectric alarm for excess impurities; ● 1 remote control/near control switch; ● 1 remote operation button box (in the coating machine head) ● 1 set of pump start/stop button, 1 power indicator light, 1 running indicator light |