Products Description

- Double motor double reducer drive cardan shaft transmission, electronic control part using PLC and touch screen tension, pressure, speed online adjustment; The hydraulic pressure is pressurized by electric booster pump, and the servo motor drives the intermediate inclined iron to automatically adjust the gap;

- Two rolling up and down arrangement, “mouth” type cast steel arch overall strong, good stability, equipped with roll disassembly device.

Work process: Active servo unwinding → taping platform → Unwinding tension detection → unwinding speed tracking swing roller → edge cutter → brush suction cartridge → Magnetic iron removal → rolling (upper and lower rollers with scrapers) → Laser online thickness measurement → Unwinding speed tracking swing roller → Unwinding tension detection → Unwinding tape platform → Active servo unwinding → Ultrasonic coil diameter detection

Technical Parameters

| Φ500 Roller Press/Calendering Machine | |

| Roll size | Φ500 * 550 (can be customized according to customer demand) |

| Roll speed | 2 ~ 12r min, stepless variable speed adjustable; |

| Rolling line speed | 2 ~ 19m/min |

| Maximum working pressure | 500KN-6000KN; |

| Roll diameter skip | ≤ ± 0.01mm |

| Roll hardness | HRC66-68 |

| Power requirements | 380V/50Hz, power 18KW; |

| Compressed air | pressure 0.5Mpa ~ 0.7Mpa flow rate |

| Total weight | abbout 10 T |

| Load bearing requirements | > 4.5 T/m2 Place a support plate at the bottom of the device. |

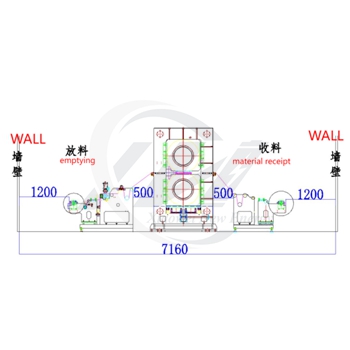

| Equipment size | The roller part is about 3100mm long x 1000mm wide x 2000mm high; The total size of the production line is about 6000mm long × 3100mm wide × 2000mm high. |