Products Description

The coating has strong binding force, microhardness of 1100-1400 HVO.3, and ultra-high wear resistance.

The coating has uniform structure and chemical composition, low porosity (< 0.06%) and does not react with the battery electrode material.

The high precision grinding machine is used to ensure that the straightness, ellipticity and coaxiality of the coated lithium electric roller are < 0.002 mm.

Coating surface roughness Ra < 0.1m; The battery electrode is not easy to stick to the roll.

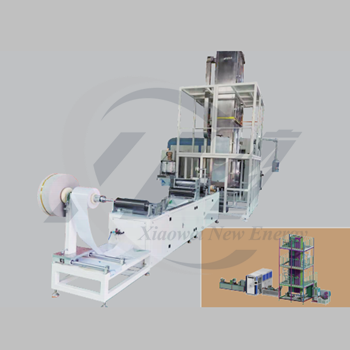

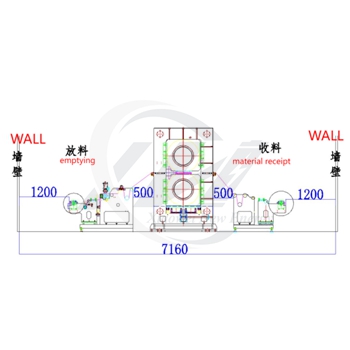

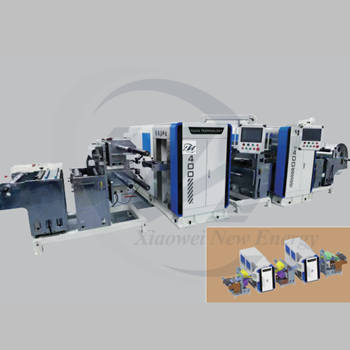

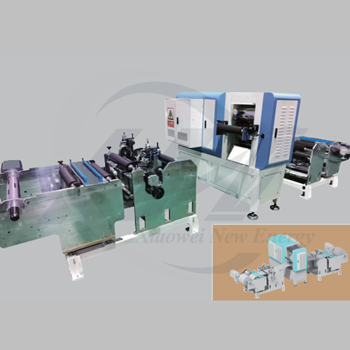

Work process:

Lithium electric high precision roller is widely used in a variety of pole-sheet rolling equipment (such as pole-sheet rolling machine, rolling mill, roll machine, etc.), the copper foil or aluminum foil matrix and coated on the matrix of the active material slurry for rolling, so that it is precisely combined into an effective pole-sheet whole.

In order to obtain high production efficiency and high quality battery electrode sheet, the high precision roller has strict requirements: high wear resistance: the roller is subjected to abrasive wear, adhesive wear and fretting wear during the working process, high wear resistance can not only maintain the precision of the roll surface and the quality of the electrode sheet, but also improve production efficiency; High density: dense tissue, low porosity, high corrosion resistance, but also to prevent the polar coating and other foreign bodies into the roll surface; High precision: the straightness, ellipticity and coaxiality of the roller are required, which can effectively ensure the uniform thickness of the battery pole.

The new thermal spraying technology is used to prepare multi-component cermet 804 coating on the surface of lithium electric high precision roller, and the high precision CNC grinding machine is equipped with the post-processing technology, and the high quality coating with high wear resistance, high density, high precision and meeting the application requirements of lithium voltage roller is developed.