Products Description

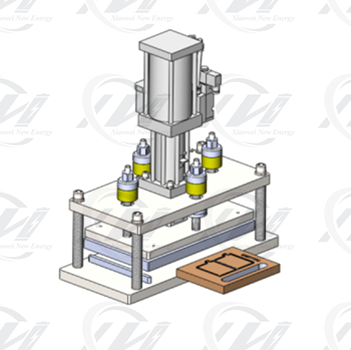

- Cathode Forming Machine is mainly used for meshing the copper tabs with the lithium electrode sheet to meet the process size requirements and make the negative electrode sheet.

- Manually transfer the lithium electrode sheet from the vacuum sucker to the positioning tool, and then put the copper pole lug into the positioning slot of the tooling, push the cylinder to the overlap of the pressing pole lug, and press the whole product into the isolation sheet box.

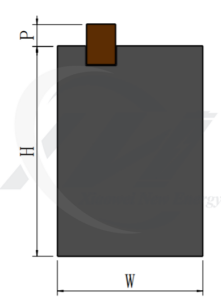

Applicable product specification range(unit :mm)

| Specification | Size |

| Length H | 50~150 |

| Wide W | 50~120 |

| The exposed tab P | ≤45 |

Material requirements:

- The pole sheet must be evenly coated, and the thickness error is less than 0.005mm without wrinkling and bonding;

- The size error of the length and width is less than ± 0.2mm, and the wave edge is less than 1mm(does not affect the pole plate positioning);

- The pole ear is flat, without bending, bending and other phenomena.

Technical Parameters

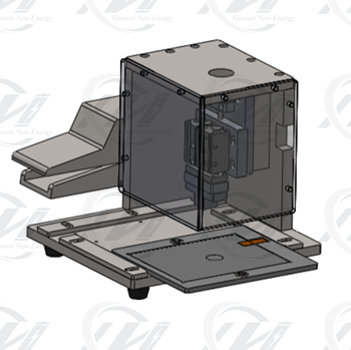

| Lithium Cathode Forming Machine For Solid State Electrode Formation | |

| Compressed air | ≥0.6MPa 20L/min (user’s own) |

| Equipment weight | Approx. 25 Kg, placed on workbench or glove box. |

| Spray color | The customer shall provide the standard color sample or the supplier’s designated color sample International pearl 16 |

| Equipment dimensions | 230*265*220mm |

Features:

- Lithium plate pole ear by the fixture positioning, accurate position;

- The adjustment and replacement fixture can be adapted to multi-specification electrode pieces;

- The workbench has a fixture positioning file fast, convenient fixture positioning and taking;

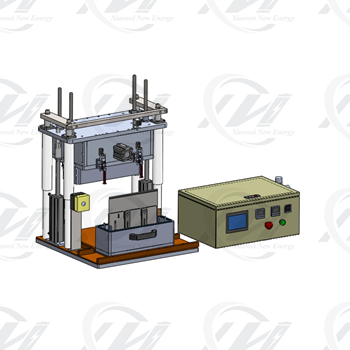

- Automatic lifting of workbench;

- The pressing head can be replaced, the pressure can be adjusted through the regulating valve