Products Description

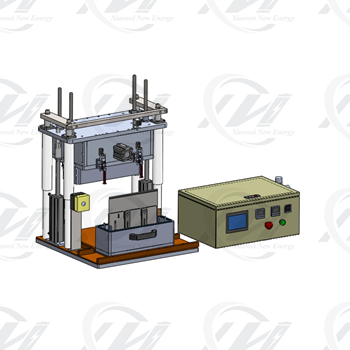

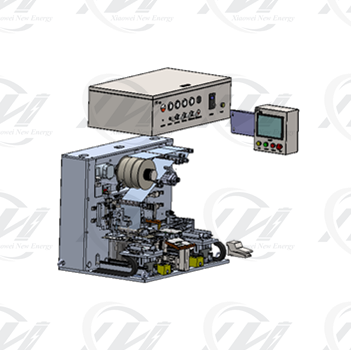

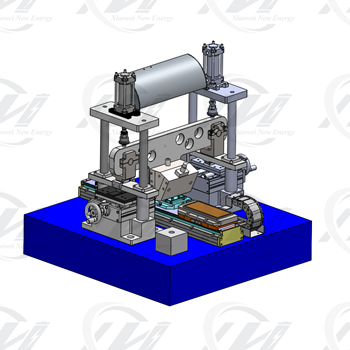

Equipment composition: Main control power supply, welding system, pneumatic system, working frame.

Working principle: The application of ultrasonic metal welding machine has 20Khz-40khz, the principle is to use the energy of ultrasonic high frequency mechanical vibration to weld the same or dissimilar non-ferrous metal materials, in the welding process neither to the workpiece transfer current, nor to the workpiece into the high temperature energy, but in the workpiece to the high frequency of 20Khz-40khz on the surface of the cycle Compound vibration, and apply the corresponding pressure to the workpiece to form a solid bond between the workpiece to achieve the welding effect.

Technical Parameters

| Ultrasonic Metal Welding For Solid State Battery Welding | |

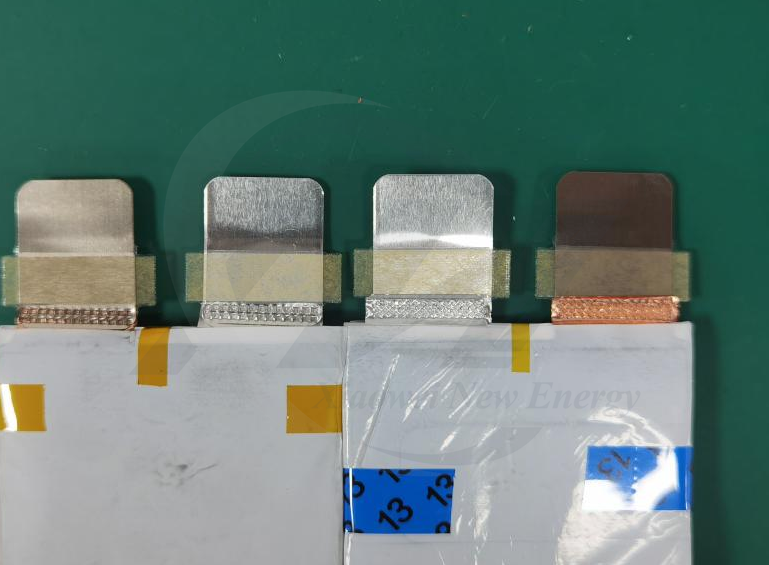

| Welding effect | ≤45 layers of aluminum foil and aluminum tabs welding,≤45 layers of copper foil and nickel tabs welding, welding firmly |

| Welding materials | Aluminum foil, copper foil 6-16um |

| Nickel sheet thickness | 0.1-0.4mm |

| Aluminum sheet thickness | 0.1 0.4 mm |

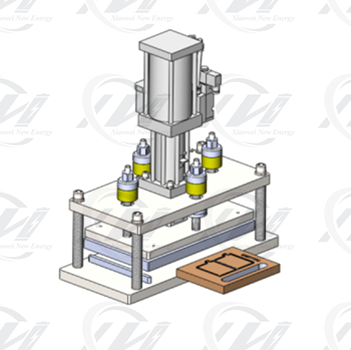

| Welding method | The welding head has two longitudinal or four transverse welding surfaces, and each welding surface has 4*12 welding points (as shown in the figure) |

| The specific shape of the welding head | The size of the solder joint of the welding head is:Solder joint length 12mm*width 4mm; The size of the bottom die is:20mm*Width 20mm*Height 45MM(customizable) |

| Power | 4200W |

| Frequency(Hz) | 20K |

|

Chassis size(cm) |

50*15*30(L*W*H) |

| Head weight(Kg)Size(cm) | 50Kg 60*25*35cm |

| Atmospheric pressure(MPa) | 0.1-0.6 |

| Welding time | Within 0.6S |

| Voltage | 220V/50Hz |

Features:

- High stability: Full digital integrated circuit, using high-performance anti-interference processor imported from the United States, increased the voltage regulation function to improve the reliability and stability of the system;

- Automatic frequency tracking: Digital frequency synthesis technology combined with digital PLL frequency tracking composite control technology, can eliminate the temperature, static load, processing area, tool wear and other factors drift the conventional analog regulator is difficult to overcome, is conducive to parameter adjustment, easy to modify the program software, easy to adjust the control scheme and realize a variety of new control strategies;

- With real-time detection of defective products:Effectively reduce the scrap rate and improve the pass rate;

- Constant power output: Intelligent closed loop amplitude control technology realizes power size adjustment, which is not affected by fluctuations in input voltage and load;

- High compatibility of resonant frequency: If the center frequency is 20.00K and the positive and negative bandwidth is 500 (HZ), the welder can work at 19.5-20.5K (HZ);

- Input voltage alarm: The mains voltage is the input AC voltage to the plug of the electrical box. When the voltage is lower than 180 V or higher than 260V, the voltage is too low or too high;

- Internal temperature alarm: Refers to the temperature on the IGBT template, when the template temperature is greater than 60°C Celsius, the device will appear overtemperature alarm;

- Welding efficiency and product pass rate: The use of American ultrasonic technology, comprehensive upgrade of technology, the main accessories are imported, the equipment works stably, the efficiency is greatly improved, and the pass rate can reach 99.99%;

- Record query welding parameters: Record the power (W), energy (J), wave time (S), frequency (KHZ), time, amplitude, count, and can record qualified and unqualified welding parameters. Can save 1-100 groups of welding process parameters.

Display