Products Description

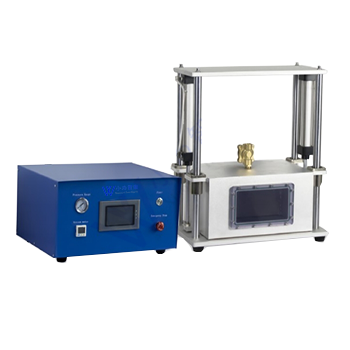

Battery Ultrasonic welding machine commonly used The laboratory battery research will use an ultrasonic welder to complete the welding of tab-tab, tab-electrode, and electrode-electrode. The ultrasonic mold welding head can be changed to complete the welding of pouch cell battery (tab-electrode welding) and cylindrical battery welding (cap-tab welding)

Ultrasonic welding machine is easy to operate, has a solid welding structure, and is stable and safe to use.

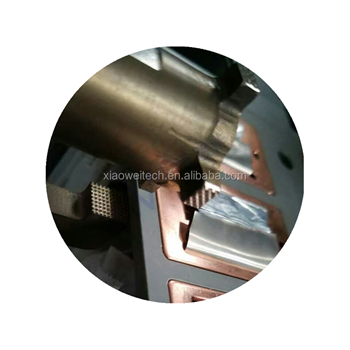

Ultrasonic welding principle: Ultrasonic metal welding machines(Battery Welding Machine) are used in the battery industry at 24.5-25.5KHz. The principle is to use the energy generated by ultrasonic high-frequency mechanical vibration to weld the same or different non-ferrous metal materials. During the welding process, no current is transmitted to the work. It does not input high-temperature energy into the work, but only performs cyclic vibrations on the surface of the workpiece at a high frequency of 24.5-25.5KHz, and applies corresponding pressure to the workpiece to form a solid combination between the workpieces to achieve the welding effect.

Automatic Ultrasonic welding machine technology in fully automated battery production line video.

XIAOWEI – About battery Welding Machine:

- Cylindrical Cell Bottom Welding Machine

- Ultrasonic Welding Machine

Pouch cell battery welding

Cylindrical Cell Welding Simple

Features

- Precision sliding bearings can ensure precise movement of the equipment and meet the best welding accuracy requirements;

- The limit can be adjusted accurately to accurately determine the upper and lower welding positions;

- The lifting speed of the welding head can be accurately adjusted;

- Welding time (ultrasonic time) can be adjusted accurately;

- The holding time can be adjusted accurately;

- The power box can still maintain stable amplitude output even when voltage fluctuates;

- Unique structural design effectively transmits ultrasonic energy to the welding head;

- The overall operation is simple, the welding efficiency is high, and the welding quality is good;

- Replaceable welding heads enable welding of various sizes;

Technical Parameters

| Welding copper aluminum universal | |

| Working voltage | AC220V/50Hz |

| Working air pressure | 0.5~0.7Mpa |

| Ultrasonic frequency | 20KHz (automatic tracking) |

| Power | 2000W (adjustable) |

| Welding time | 0~15s |

| Solder joint | 5*5mm |

| Welding substrate | Positive electrode: A. Aluminum foil 0.015-0.020mm B. Pure aluminum strip 0.1-0.2mm;Negative electrode: A. Copper foil 0.009-0.012mm B. Copper nickel-plated tape 0.1-0.2mm; |

| Welding layer | within 40 layers |

| Drive form | pneumatic |

| Equipment weight | about 60Kg |

| Control box size | L360×W480×H200mm |