Products Description

What is lithium battery electrode piece making/production?

Lithium battery production process – production process: Lithium battery electrode piece production is to automatically welding the electrode tabs according to the required parameters after the electrode pieces are cutting by the slitting machine/cutting machine.

Completion process:

- Install the electrode lug material and high-temperature tape, adjust the equipment parameters of the corresponding model, then install the cut pole roll, and enter the film machine through traction;

- Ultrasonic Spot Welding System:

- Spot welding tabs that meet process parameters;

- Precisely weld in the gap between the pole pieces and the foil;

- The positive tab is welded in the middle of the electrode piece required for battery winding;

- The negative electrode tabs are welded to both sides of the electrode pieces required for battery winding.

- High temperature tape for electrode tabs:To achieve the insulation effect and prevent short circuit of the electrode pieces, collect the electrode pieces with welded tabs into electrode piece rolls;

- Battery electrode making process completed.

The electrode making machine corresponds to the solution for the winding process of cylindrical batteries/pouch cell batteries, and corresponds to another equipment (die cutting + stacking machine). The stacking process makes electrodes.

Xiaowei can provide fully automatic film making machines for pilot battery production lines, as well as fully automatic film making machines with integrated winding functions.

Technical Parameters

| Electrode Making Machine – Material Parameters(For more equipment information, please contact us) | ||||||||

| Types | Feeding method | Material single piece length(mm) | Materials width(mm) | Base material thickness(μm) | Maximum outer diameter | Inside diameter | ||

| Size range | Size range | Tolerance | Size Range | Tolerance | (mm) | (mm) | ||

| Electrode | Roll material | 300-1800 | 30-80 | 0.2 | 50-280 | 5 | ф400 | ф76.2 |

| Electrode Tabs | Roll material | 30-70 | 3-5 | 0.2 | 100-300 | 5 | ф400 | ф76.2 |

| Tape | Roll material | 30-80 | 5~20 | 0.2 | 20-80 | 5 | ||

Xiaowei’s complete electrode making machine solution – reliable communication, fast response, convenient operation, and high efficiency

- CTH300 series PLC has large program and data space, strong expansion capability, and fast processor scanning speed;

- High-speed EtherCAT bus control scheme, simple wiring, high control accuracy, fast speed and real-time response;

- The monitoring screen of the TP07i touch screen enables independent operation and independent debugging of each work station to ensure the coil yield rate;

- Using operation interruption positioning, when executing the interruption, the positioning is completed in one step according to the set position, and the positioning is accurate;

- The production efficiency has been greatly improved, from 1.7s/pcs of the ordinary model to 1.48s/pcs of this solution.

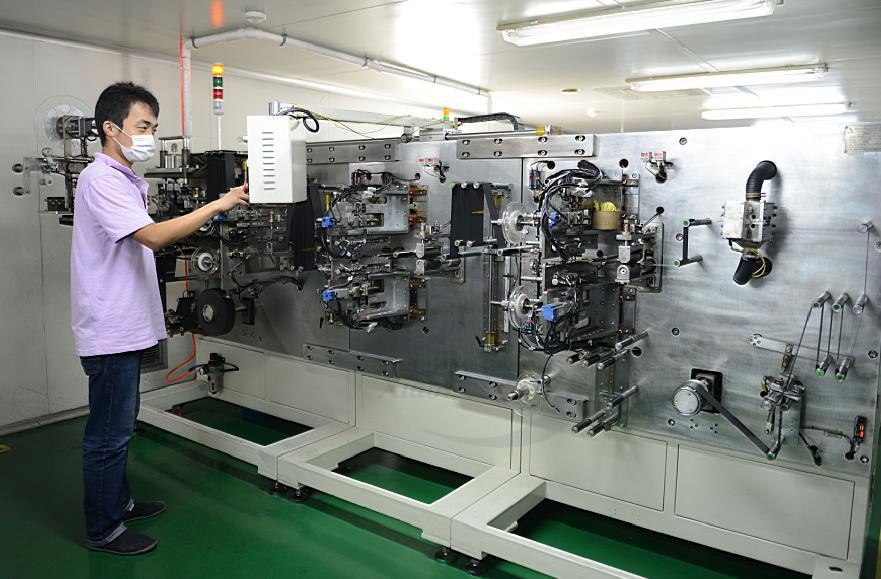

Equiment Display