Products Description

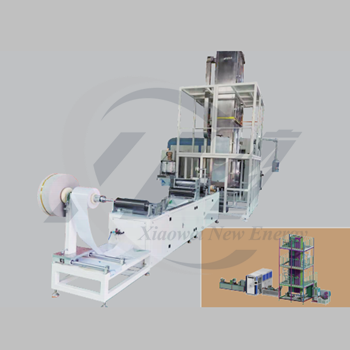

The whole production process automatically carries out the production process of the battery electrode steel strip automatic correction and discharge, tape connection, tape storage device, steel tape gluing paper device, automatic feed and sizing machine, sizing, drying, prepressure traction, tension synchronization, tape tearing, roll pressing, kneading powder dust absorption, slitter and cutting.

Work process: Automatic unwinding → correction → Manual welding of steel tape → storage tape → Tape gluing paper → Automatic sizing, mold sizing → 6.5m (6 stage) drying furnace → Main drive traction device → tension synchronization belt correction device → Tear tape → roll press → kneading sheet → Powder cleaning device → pole sheet roller cutting sheet → Receiving material.

Technical Parameters

| Nickel-Metal Hydride Negative Wet Production Line | |

| Power requirements | 380V/50Hz (three-phase AC power supply) |

| Total power |

95KW (including 72KW heating power) |

| Mechanical transmission speed | 0.5m-7m /min(variable frequency adjustable) |

| Vertical drying furnace each furnace 12KW traction line speed | 0-8 meters adjustable. |

| Sizing mold | width 230mm with 90w speed motor stirring. |

| Scraping | width 0-22mm, scraping length accuracy ± 0.2mm. |

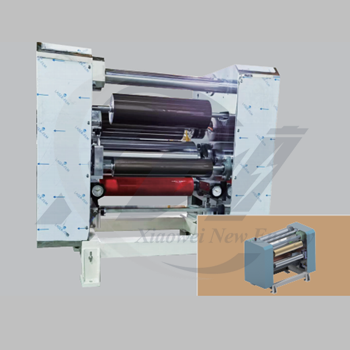

| Roller machine | Yujia standard with all models can be |

| The roll diameter of the kneading machine | Φ160mm. The drawing machine adopts 200w speed regulating motor, and the rolling precision is ± 0.01MM. |

| Cutting knife width | 300mm, |

| Slitting knife | 20-100mm |