Products Description

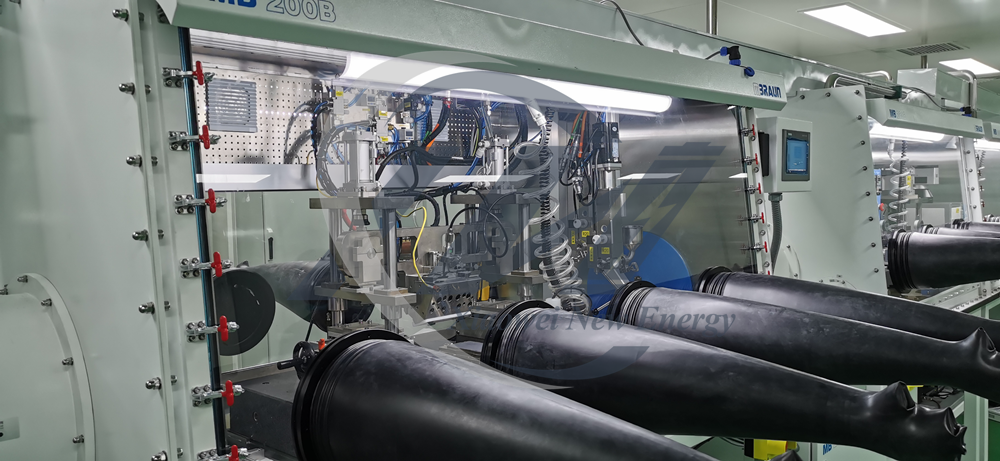

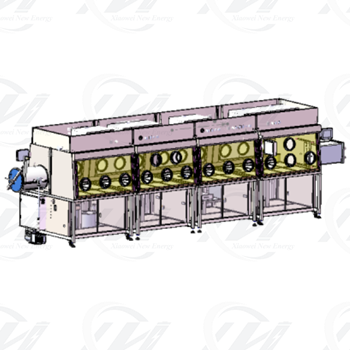

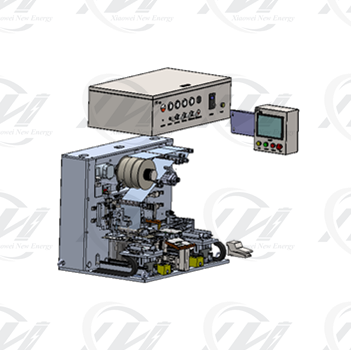

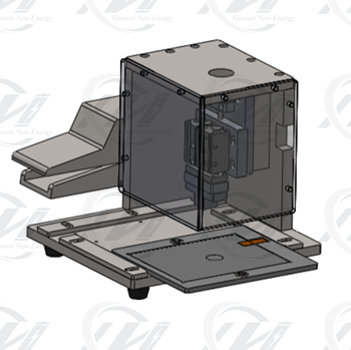

The glove box system is an 8-station glove box system, operated opposite to each other, including glove box box, 2 sets of single-column circulation purification system, water oxygen analyzer, vacuum system, etc. The control system adopts Siemens PLC and touch screen operating system, the operation interface is intuitive and simple. Glove box housing with angled detachable high penetration safety glass front window and butyl rubber gloves, etc. Housing volume: approximately 4m3 Overall leakage rate meets the following criteria: Testing according to ISO 10648-2 standard (Oxygen Method) : typical data < 0.05vol %/ hour; Water oxygen index; water 1ppm oxygen 1ppm.

Technical Parameters

| Vacuum Glove Box System For Solid State Battery Production | |||||||||||||||

| Glove box body |

|

||||||||||||||

| Bottom frame | Pull 40X60 carbon steel pipe, height 920mm, with adjusting feet and casters | ||||||||||||||

| Main pipe | 304 stainless steel material, diameter; DN40.KF40 Fast interface | ||||||||||||||

| Circulating main valve | Electrically controlled pneumatic bellows sealed vacuum Angle valve,diameter:DN40 | ||||||||||||||

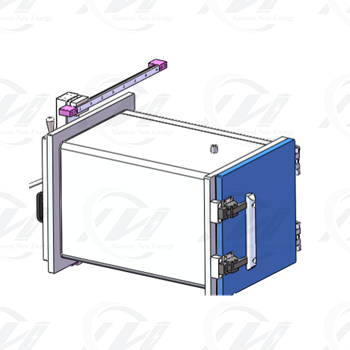

| Large transition chamber | One on the left and one on the left, heating mechanism on the left, internal diameter 360mm, length 600mm; Valves control pumping and charging; Slide tray, two-way pull out more than 50%, the items more convenient to take and place; Transparent tempered glass cabin door, cabin contents; The inner and outer doors are equipped with gas-spring controlled lifting systems; The right side is the square cabin, the inner dimension length is 600*360*360mm; Valves control pumping and charging; Slide tray, two-way pull out more than 50%, the items more convenient to take and place; Aluminum handle door, inner sliding door, outer door flat open structure | ||||||||||||||

| Small transition cabin | left side, diameter 150mm, length 300mm; Valves control pumping and charging | ||||||||||||||

| Box front window | ultra-white high-permeability safety tempered glass, thickness 8mm;Integral cast double sealing ring | ||||||||||||||

| Glove mouth | 34 aluminum alloy surface anodized, diameter 220mm, using O-ring seal | ||||||||||||||

| Gloves | 34,top acid, alkali and corrosion resistant, butyl rubber material, thickness 0.4mm | ||||||||||||||

| Vacuum pump | 2 ATLAS GVD 12 (EDWARDS RV12), 3X10-2 mbar vacuum, 2X10-3 mbar ultimate vacuum,with oil mist filter | ||||||||||||||

| Circulating fan | vacuum sealed package,maximum flow of 90m3/h;Siemens inverter control flow | ||||||||||||||

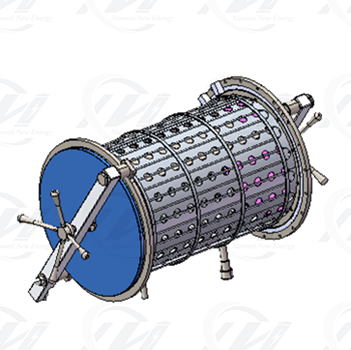

| Purifier | German BASF and United States UOP purification material, under standard conditions can remove 36 liters of oxygen, remove 1.3Kg of water; Regenerated gases: nitrogen/hydrogen mixture (5-10% hydrogen) or argon/hydrogen mixture (5-10% hydrogen); The bottom is filled with heat storage conductive material | ||||||||||||||

| Organic solvent adsorber | Built-in dust-free activated carbon 6L,series in the pipeline | ||||||||||||||

| Water analyzer | EM-MT-100, detection range,0-500ppm; Designed for the glove box atmosphere, phosphorus pentoxide type platinum sensor, corrosion resistance, users can carry out their own probe regeneration cleaning, no need to return to the factory processing, design life must be more than 5 years; PLC control, touch screen display | ||||||||||||||

| Oxygen Analyzer | EM-OT-100, measuring range; 0 ~ 1000 ppm, zirconia type sensor, can be exposed to air for a long time, design life must be more than 5 years; PLC control, touch screen display | ||||||||||||||

| Control system | there is a foot pedal that can adjust the pressure in the box, the pressure adjustment range is ±10mbar; Siemens PLC; Fast response color 7-inch touch screen,128M storage space, no hysteresis in operation, with USB historical data dump interface | ||||||||||||||

| Lighting system | LED fluorescent tube is installed in the upper end of the front window of the box, and equipped with anti-diffusion function, controlled by PLC | ||||||||||||||

| Power supply | 220V/50HZ | ||||||||||||||

| Operation bits | left and right | ||||||||||||||

Equiment Display