Battery Process

More Custom Items

Xiaowei New Energy

The production and research of button/coin cell batteries is very simple. It requires relatively little equipment, punching and sealing, and then configuring the mold to complete the production of button/coin cell batteries.

Battery Process: Lab Coin Cell Battery Process

The production and research of button/coin cell batteries is very simple. It requires relatively little equipment, punching and sealing, and then configuring the mold to complete the production of button/coin cell batteries.

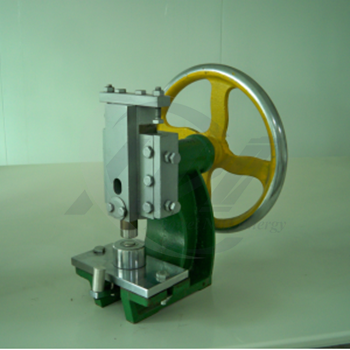

Battery electrode and film die-cutting

It is mainly used for punching and cutting button batteries. It can be equipped with different sizes of punching molds. It is suitable for button batteries of various sizes. The thickness can reach 0.005-0.5mm.

Battery electrolyte transfer

Complying with human body mechanics, exquisite and compact, simple and practical, it is mainly used to transfer electrolyte to small button batteries.

Button battery sealing and crimping

It is widely used in the sample production and research of laboratory button batteries. It is manual and equipped with different molds to realize battery disassembly and picking up research, battery electrode pressing and other operations.