Products Description

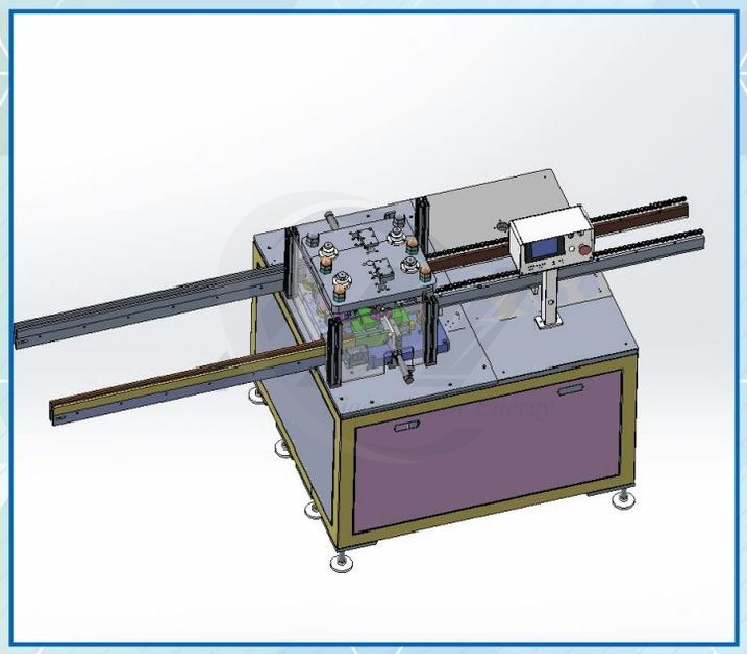

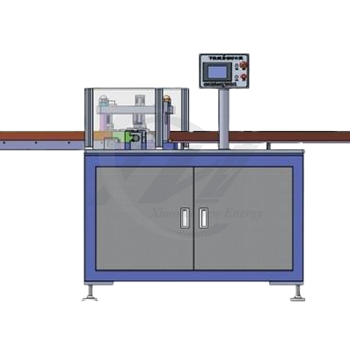

Automatic cylindrical battery sealing machine used in pilot line production: The equipment mainly punches and seals the cylindrical battery steel shell after liquid injection.

Brief overview of equipment operation: Put the entire battery row into the feeding conveyor belt; when the battery is detected by the pushing cylinder sensor, the pushing cylinder will push the battery forward to the sealing area. The upper mold plate is pressed downward. While pressing, the lower mold will tighten first, and the upper grinding tool will be compressed, causing the wedge to push the lower mold for sealing. When stamping is completed, the upper template is retracted, the lower template is opened, and the next action is cycled. Each battery must enter each sealing position to complete the sealing.

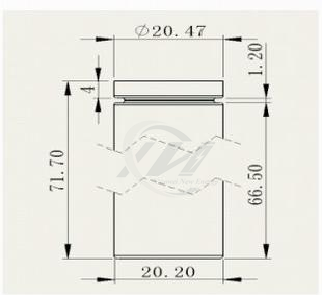

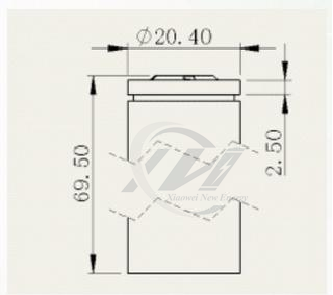

Before and after battery sealing: 20700

Technical Parameters

| Cylindrical Cell Automatic Sealing Machine For Battery Polit Line | |

| Working temperature range | 0~40 |

| Humidity | below 75% |

| Venue | No pollution and strong electromagnetic interference |

| Maximum size of equipment | 1150mm(L)x700mm(W)x1500mm(H) |

| Weight | about 520Kg |

| Working voltage | AC380V±10V 50Hz |

| Power consumption | ≤4KV |

| Capacity | 55±5ppm |

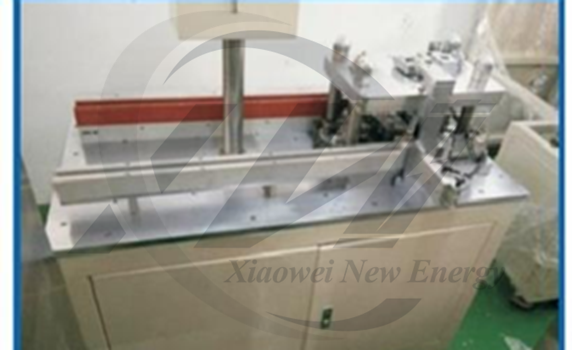

Equiment Display