Battery Process

More Custom Items

Xiaowei New Energy

Laboratory cylindrical battery research requires a lot of equipment. After the electrode are prepared, the battery cell needs to be made into a cylindrical shape through the winding equipment, and then installed into the cylindrical battery shell. After a series of welding operations, the battery cell of the cylindrical battery is completed. battery cell assembly, final injection of electrolyte, and sealing to complete the cylindrical battery.

Research on common 18650, 21700, 32650, 4680 and other cylindrical batteries.

Battery Process: Lab Cylindrical Cell Battery Process

Laboratory cylindrical battery research requires a lot of equipment. After the electrode are prepared, the battery cell needs to be made into a cylindrical shape through the winding equipment, and then installed into the cylindrical battery shell. After a series of welding operations, the battery cell of the cylindrical battery is completed. battery cell assembly, final injection of electrolyte, and sealing to complete the cylindrical battery.

Research on common 18650, 21700, 32650, 4680 and other cylindrical batteries.

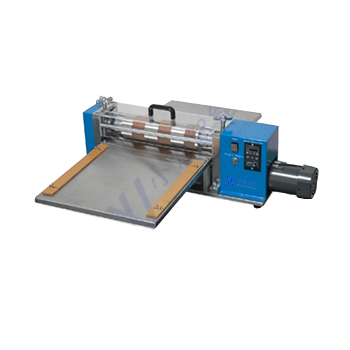

Disc battery electrode punching and cutting process

Cut the coated continuous cathode and anode electrode to the length and size that conforms to the battery cell. The cutting equipment can set the cutting length, quantity, speed, separate cutting, and has automatic rewinding and unwinding functions, tension Controls automatic feeding and stopping, easy loading and unloading.

Battery cathod and anode electrode slitting

It is mainly used for roll-cutting and slitting of positive and negative electrode sheets after battery coating. The wide electrode sheets are divided into multiple strips, and the edges of the slices are neat to ensure dimensional accuracy.

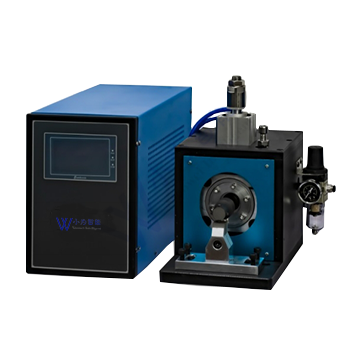

Weld the battery tabs to the electrode

Ultrasonic tab metal spot welding machine is generally used for metal welding in winding and lamination processes (tab welding, tab and electrode welding). It has the characteristics of small size, beautiful appearance, easy operation, solid structure, stable and safe use. In laboratory welding, ultrasonic welding is usually used, not laser welding

Wind the positive and negative electrode sheets and separator into a battery cell

The laboratory small winding machine is specially used for the core winding process of aluminum foil Cylindrical cell/pouch cell batteries. the positive and negative electrode sheets and separators are manually wound into battery cores. Easy to operate, safe and reliable

Single-pin spot welding of cylindrical battery negative electrode plate and casing

Using AC pulse spot welding machine (single needle spot welding), controlled by microcomputer microcontroller, the performance is more stable and reliable. It is a necessary equipment for the production of cylindrical lithium batteries.

Fixed position of cylindrical battery cells

The cylindrical battery with the battery core and no seal is rolled and grooved (to compress the battery space and fix the battery core). The mold can be replaced and is suitable for a variety of batteries such as 18650, 21700, etc.

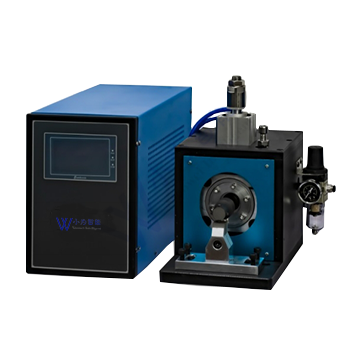

Welding of battery positive tab and cylindrical cap

The ultrasonic spot welder can not only weld pole pieces and tabs.

It can also be used to weld the positive electrode sheet and battery cap.

The battery electrolyte is standing in a vacuum environment

This high-efficiency equipment integrates vacuum mixing and dispersion. It is suitable for the mixing process of positive and negative electrode slurries in battery experimental research. It is completely bubble-free.

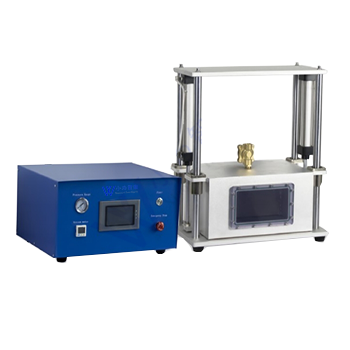

Final sealing of cylindrical cells

The small manual hydraulic cylindrical battery sealing machine is mainly used in the production of cylindrical batteries, and the final sealing and molding of cylindrical batteries.