Products Description

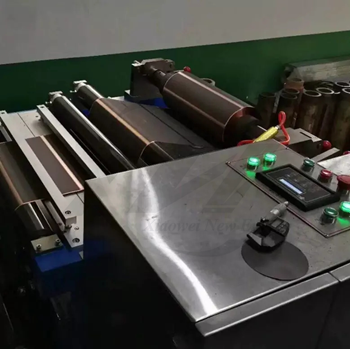

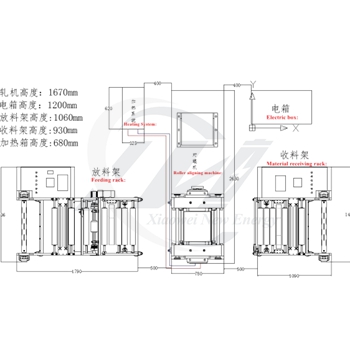

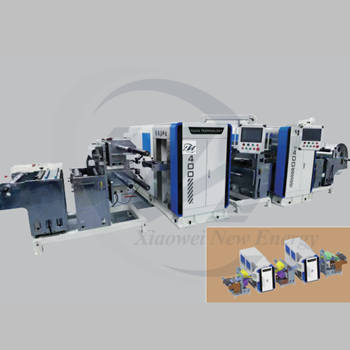

Used in lithium battery/new energy battery production – battery rolling press machine, which coats or cuts the electrodes and then rolls them. Surface density can be increased by pressing the electrodes.

The rolling process is an important process in battery manufacturing. The effect of rolling can greatly affect the energy density and cycle times of the battery. Rolling machines also have some models based on rolling width and rolling method.

Currently, Xiaowei’s solutions and equipment can produce lithium batteries with a cycle life of up to 2,000 times.

Technical Parameters

|

Battery Rolling Press Machine For Battery Production: Roller Size 500mm-800mm(Can be customized)

|

|||

|

Roller size

|

500*500mm

|

600*600mm

|

800*800mm

|

|

Pole sheet width

|

200~500mm

|

200~550mm

|

300~750mm

|

|

Output speed

|

2~11rpm

|

2~10rpm

|

3~12rpm

|

|

Roll straightness speed

|

4~17m/min

|

4~19m/min

|

6~30m/min

|

|

Roller surface roughness

|

Ra≤0.2

|

Ra≤0.2

|

Ra≤0.2

|

|

Roll cylindrical degree

|

≤2.0μm

|

≤2.0μm

|

≤2.0μm

|

|

Roll thickness accuracy

|

±2.0μm

|

±2.0μm

|

±2.0μm

|

|

Roll pressure range

|

100~300t

|

100~300t

|

100~300t

|

|

Roll gap adjustment range

|

0~2.0mm

|

0~2.0mm

|

0~2.0mm

|

|

Roll gap adjustment accuracy

|

1μm

|

1μm

|

1μm

|

|

Tension adjustment range

|

2.2~20kg

|

2.2~20kg

|

2.2~20kg

|

|

Orderly winding error

|

±0.5mm

|

±0.5mm

|

±0.5mm

|