Products Description

Automatic Aluminum Film Punching Machine is suitable for punching and cutting polymer (pouch cell battery) lithium battery electrode pieces. The machine has a simple structure and is easy to operate. During operation, place the cut large piece of pole piece on the die, push the die to the punching position, press the start button with both hands, the upper die is closed, release the button, the upper die opens, and the pole piece is completed. of punching.

Aluminum plastic film forming machine, automatic shell punching machine, automatic shell breaking machine, aluminum plastic film bag making machine.

Equipment workflow

Manual feeding → Connecting platform → Tension control → Dust removal → Static removal → Punching → Rolling cutting → Servo pulling → Crosscutting mechanism → Finished product collection.

Technical Parameters

| Automatic Aluminum Film Punching Machine – Punching Parameters | |||

| Item | Size (mm) | Accuracy | Remark |

| Punched length | 50-300 | / | Customer provide the acceptance size |

| Punched width | 40-200 | / | |

| Length of aluminum laminated film | 25-350 | ±0.2 | |

| Width of Aluminum laminated film | 40-200 | ±0.5 | |

| Top-side size | 3-20 | ±0.2 | |

| Punching thickness | 2-10 | ±0.15 | |

| Device parameters | |

| Punching mode | One mold punching one pouch cell |

| Feeding mode | Feeding in roll, automatic correction, motor unwinding, tension control. |

| Size of aluminum laminated film | Width≤350mm, inner diameter: 3 inch, outer diameter<450mm |

| Tension control | Aluminum laminated film tension control is electric proportional valve + low-friction cylinder + potentiometer combined with servo motor to control the tension. |

| Discharge mode | Chute discharge (waste materials are collected separately), taken out manually from the material box. |

| Accurate of punching depth | ± 0.1mm (four corners), the touch screen can set the accuracy to 0.01mm |

| Overall punched dimension accuracy | ±0.15mm (mold size and clearance guarantee) |

| Max size of aluminum laminated film | L350mm * W200mm |

| Punching depth adjustment | Add gaskets on the mold(servo adjusts the depth of the mold punching) |

| Punch pressure range | 3T |

| Punching model | Servo punching |

| Mold life | 1 million times |

| Appearance of the punched case | The corners are smooth without wrinkles and pinholes, and the surface is smooth without concave convex pits, scratches, cracks, etc. |

| Transport mode | Servo transporting (set in touch screen) |

| Transport accurate | ±0.1mm |

| Crosscutter mode / position adjustment mode | Cutting / servo adjustment (set in touch screen) |

| Cutting accurate | ±0.2mm |

| Cutter (tungsten steel) life | 1 million times (repairable) |

| Mold replace time | 1-2h |

| Capacity | ≥10ppm (one mold punching one pouch cell) |

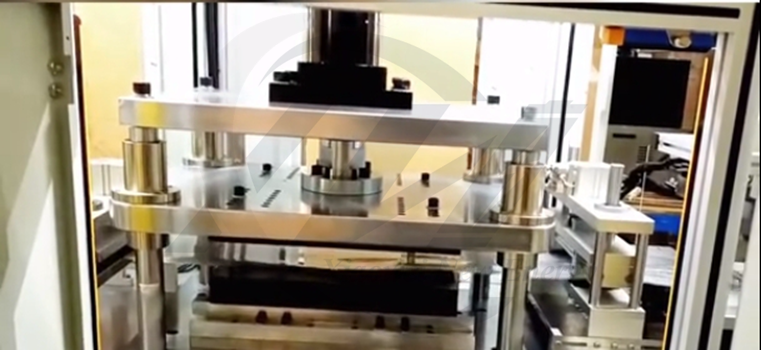

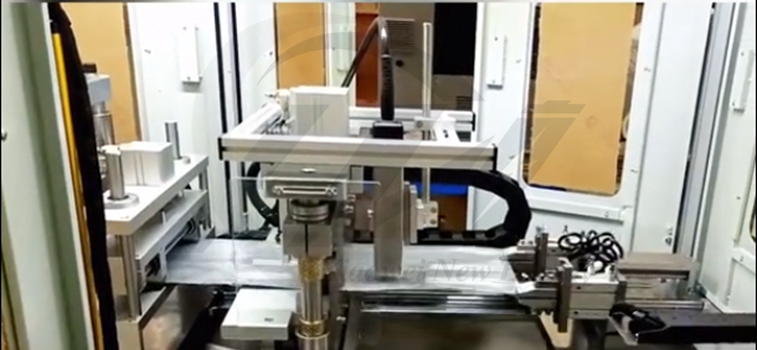

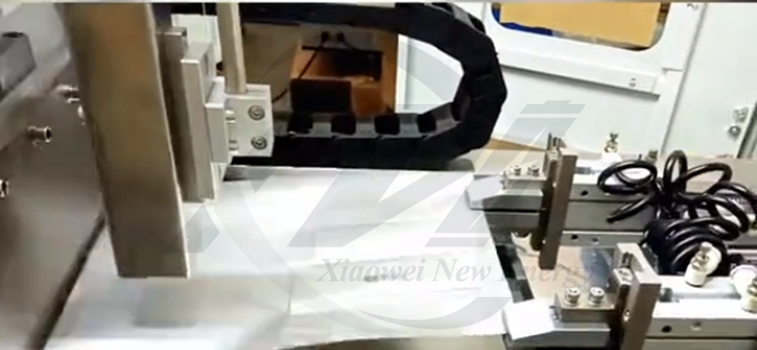

Equiment Display