Products Description

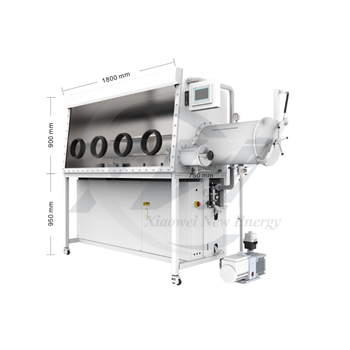

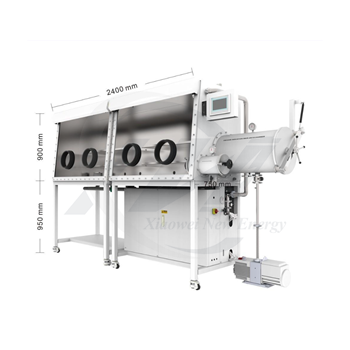

The Lab1800 system includes a sealed box, a transition chamber, a rotary vane vacuum pump and a circulation purification system integrated with a microcontroller operation panel. The inert gas purification system equipped with the standard Lab1800 system installs a set of purification columns (fully automatic and regenerable) to purify and maintain the gas environment inside the glove box.

Technical Parameters

- Material: Stainless steel 1.4301 (SUS type 304), thickness 3 mm

- Glove Box Chamber:1200mm(L) x 750mm(W) x 1850mm(H);

- Volume: 1.2 m³

- Power:3000W;

- Volume: 1.0 m³;

Cabinet parameters:

- Front window panel: 8 mm thick safety tempered glass or 10 mm thick polycarbonate (optional);

- Front window size: 1123mm(L) x 839mm(H);

- Glove material: butyl rubber;

- Glove thickness: 0.4 mm or 0.8mm (optional);

- Filters Outlet and inlet filters, filtration <0.3μm.

GP20 gas purification system:

- Automatic removal of H2O and O2, single purification column system, automatic regeneration (GP200 double purification column optional), closed gas circulation pipeline;

- Operating voltage: AC 230 V / 50-60 Hz, 10 A or AC 115 V / 50-60 Hz, 20 A (optional);

- Working gas: N2, Ar, He (purity ≥99.999%);

- Regeneration gas: H2 accounts for 5%-10%, and the rest is working gas (purity ≥99.999%);

- Vacuum pump specifications: rotary vane vacuum pump, equipped with oil mist filter, with gas ballast control;

- Vacuum pump flow: 12 m³/h (7 cfm), dual-chip, vacuum < 2 x 10-3 mbar or dry pump (optional);

- Circulation unit: oil-free high-speed fan;

- Air volume: 80 m³/h;

- Valve KF40 high vacuum valve.