Battery Process

More Custom Items

Xiaowei New Energy

Laboratory pouch cell batteries is divided into two processes, lamination and winding (winding is similar to cylindrical). Each process uses different equipment, mainly lamination machines and winding machines, as well as some electrical equipment. The core processing equipment is different. Pouch Cell batteries have good scalability and a wide range of applications, ranging from 3C digital products to power vehicles, etc.

Battery Process: Lab Pouch Cell Battery Process

Laboratory pouch cell batteries is divided into two processes, lamination and winding (winding is similar to cylindrical). Each process uses different equipment, mainly lamination machines and winding machines, as well as some electrical equipment. The core processing equipment is different. Pouch Cell batteries have good scalability and a wide range of applications, ranging from 3C digital products to power vehicles, etc.

Stacking Process

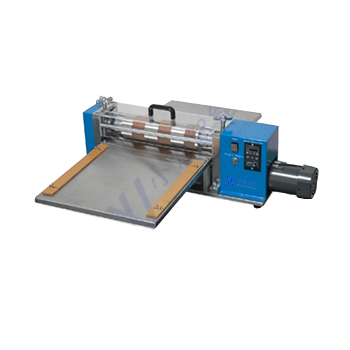

Battery electrode slitting

Slitting machines are often used together with cutting machines to cut electrode sheets of any size

Battery electrode winding

The manual battery winding machine winds the battery core into a cylindrical shape. Winding Process

Pouch cell tab welding

Battery Ultrasonic welding machine commonly used The laboratory battery research will use an ultrasonic welder.

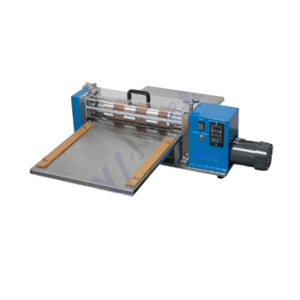

Hot rolled battery core

Hot Press Machine(Pouch Cell hot press) is suitable for hot-pressing and shaping the rolled cells of pouch cell batteries into a flat shape.

Winding Process

Die-cut electrode according to mold size

The semi-automatic electrode die-cutting machine is used in the lamination process. Stacking Machine

The stacking process of electrode sheets

Battery Stacking machine is used for the lamination process of battery cells to laminate the positive and negative electrode sheets and separators.

Pouch cell tab welding

Battery Ultrasonic welding machine commonly used The laboratory battery research will use an ultrasonic welder.

Punch out aluminum shells of specific sizes

The semi-automatic aluminum laminated film forming machine is suitable for punching and forming aluminum-plastic film shells for pouch cell lithium batteries.

pouch cell side sealing

pouch cell sealer machine is mainly suitable for the packaging of the top side and side of the flexible packaging lithium battery.

Vacuum standing electrolyte

The Electrolyte Diffusion Chamber(Vacuum Standing Box) is mainly suitable for absorbing electrolyte when filling pouch batteries and cylindrical batteries.

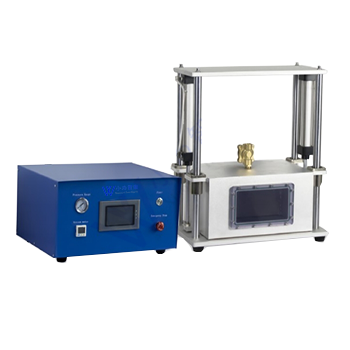

Under vacuum conditions, pre-sealing

(Pre-Sealing) Vacuum Pouch Sealing Machine is used for vacuuming and hot-pressing pre-sealing of pouch cell batteries after they are filled with liquid and left to stand.

Pouch cell battery formation treatment

Hot Press battery Formation equiment is used for hot pressing of 16-channel single-ended electrode batteries, The machine and equipment adopt a horizontal structure.

Pouch cell battery final sealing

The pouch cell battery final sealing machine is mainly used for standing vacuum and hot-pressing packaging of pouch cell batteries after liquid injection.

Cut off the excess corners of the pouch cell battery

Pouch Cell Cutting Edge Machine After the final sealing of the pouch cell battery, the excess aluminum plastic film edge is cut off and cut into the pouch cell battery of the final required size.