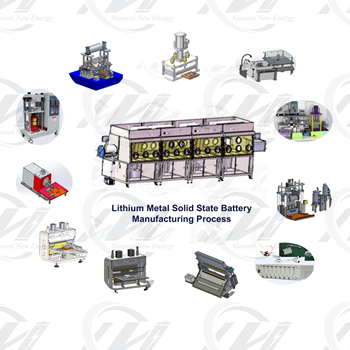

Products Description

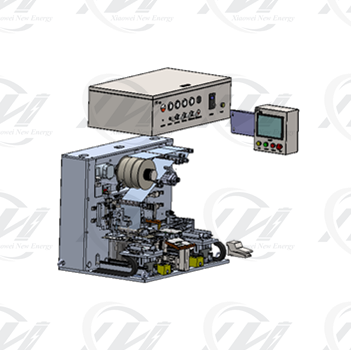

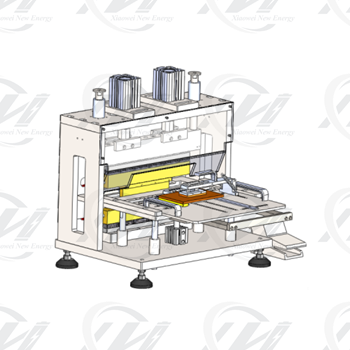

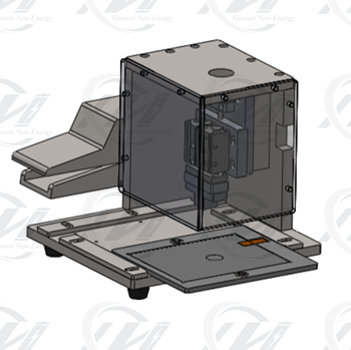

Placed in the glove box, the equipment is mainly used to glue the positive and (lithium) negative electrode sheet and the isolation film of the metal lithium negative electrode cell to make a Z-shaped laminated film to make a battery cell.

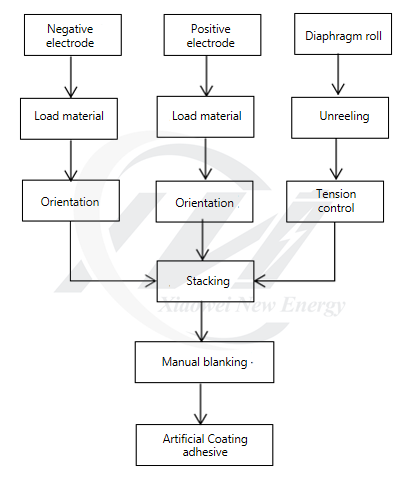

The lithium anode uses a single-layer sheet box to be manually switched as a loading positioning platform. The box and positioning platform are positioned by pins and moved to the loading position (the lithium anode sheet box is completed in another process); it is also compatible with secondary battery carbon anodes. Material box (multi-layer sheet material).

The positive electrode pick-up mechanical arm mechanism uses vacuum to pick up the electrode pieces in the positive electrode trough, and the secondary positioning correction mechanism accurately positions them;

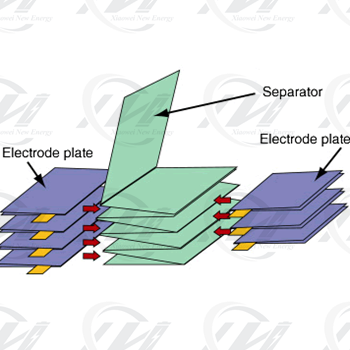

The positive and negative electrode sheets are alternately placed on the stacking table; the stacking table moves back and forth between the two robotic arms in conjunction with the movements of the two robotic arms, so that the isolation film forms a Z-shape to separate the positive and negative electrode sheets; the equipment moves in such a cyclical manner to achieve the polar assembly When the number of laminated sheets reaches the set value, the cell transfer manipulator will send the pole group clamp to the (reserved length of the rolled separator) cutter to cut the separator, and the manipulator rotates to the cell unloading position, and the equipment Automatically enter the assembly of the next pole group;

The cells are collected manually, and the diaphragm is finished and glued manually.

Technical Parameters

| Stacking Machine For Solid State Battery Electrode Laminated | |

| The outer diameter of the diaphragm roll is <Φ200mm, the inner diameter of the roll core is 3″, the width is 40-100mm, and the thickness is 0.017-0.04mm; | |

| Equipment speed | 2.0~3.0 seconds/piece*number of pieces+finishing time 15 seconds (depending on product specifications and material composition); |

| Product qualification rate | 98% (excluding reasons for incoming materials) |

| Equipment utilization rate | 95% (except for incoming materials) |

| The diaphragm is automatically unrolled and the working tension is adjustable | |

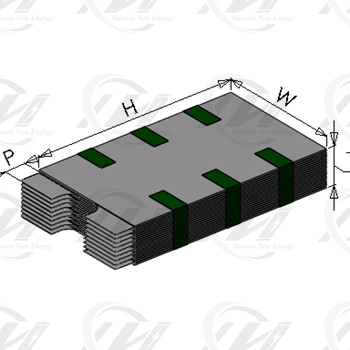

| Diaphragm lamination accuracy | battery core/cell thickness 5-20≤±0.2mm (end surface alignment) |

| Electrode stacking accuracy | battery core/cell thickness 5-20≤±0.2mm (center deviation value) |

| Lamination accuracy of diaphragm and pole piece | battery core/cell thickness 5-20≤±0.2 mm (center deviation value) |

| material requirements | The electrode piece must be coated evenly, with a thickness error of less than 0.005mm without wrinkling or sticking; the length and width size error must be less than ±0.2 mm, and the wavy edges must be less than 1mm (does not affect the positioning of the electrode piece); the pole tabs are flat, without Bending, breaking and other phenomena. |

Features:

- The machine is equipped with leakage protection switch, with correct grounding measures, to protect the human body from electric shock;

- The machine is controlled by touch screen, and alarm is given when illegal operation and various faults occur;

- The transmission part and the working part of the whole machine are equipped with safety protection devices;

- Whether automatic or manual, there will be no misoperation before and after to avoid danger;

- The base of the equipment is made of aluminum to ensure the supporting strength and operation stability of the whole machine. The outer cover is an electrophoretic aluminum profile frame, protected by transparent acrylic plate.