Products Description

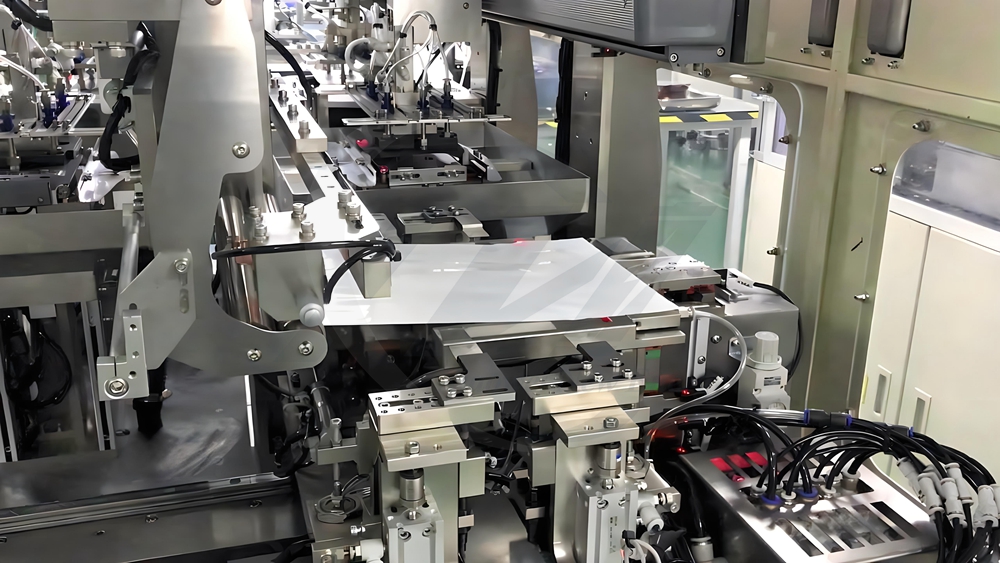

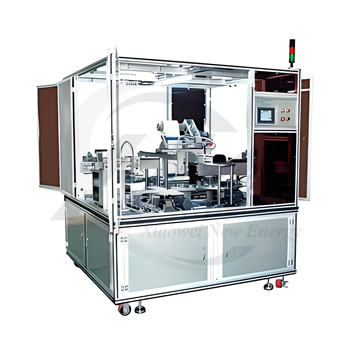

Xiaowei’s fully automatic lamination solution, high speed and precise positioning, meets the needs of large-scale lithium battery production.

Automatic lamination of battery cells is one of the key equipment for automated production of square lithium batteries.

This equipment is suitable for assembling the positive and negative electrodes of lithium-ion battery cells and the isolation film into Z-shaped laminations. It automatically wraps the isolation film in the electrode group, automatically cuts off the separator, automatically affixes the anti-loosening tape, and automatically unloads the material to the material rack, manually collect the cells in the material rack.

Technical Parameters

| Lithium battery Automatic Stacking Machine -Stakcing Process Material Parameters | ||||||

| Specification material | Incoming materials | length | width | Thickness um | Inside diameter | Maximum outer diameter |

| positive electrode | piece | 65-190 | 25-100 | 100~280 | – | – |

| negative electrode | piece | 65-190 | 25-100 | 80~280 | – | – |

| positive tabs | – | ≤30 | 10-50 | – | – | – |

| negative tabs | – | ≤30 | 10-50 | 8~20 | – | – |

| separator film | roll | – | 33-186 | 16~45 | φ76.2 | Φ250 |

| Stacking Machine More Parameter Details | |

| Size | W2460 x L2000 x H2335mm |

| Single chip efficiency | 1.1-1.3s/pcs |

| Alignment accuracy between pole piece and diaphragm | Center deviation ±0.5mm |

| Diaphragm end face positioning accuracy | ±0.5mm (except tail roll diaphragm) |

| Alignment accuracy of adjacent pole pieces | ±0.3mm |

| Overall alignment accuracy of pole pieces | ±0.5mm |

| Number of laminated layers | Can be set within the thickness adaptation range |

| Operation rate | 95% (faults caused only by this machine) |

| Qualification rate | 99% (only defects caused by this machine, defective incoming materials will be eliminated) |

Automatic stacking machine equipment features:

- The positive and negative electrodes are configured in a single trough, and the pole piece in the trough has a real-time floating structure;

- The use of slight bending, brushing, shaking action and elastic suction cups can effectively prevent the phenomenon of multiple pieces being sucked;

- Secondary precise positioning to ensure pole piece alignment;

- The positive and negative electrode pressing claws alternately press the positive and negative electrode sheets to prevent cross-contamination;

- The positive and negative electrode troughs are separated by partitions before lamination to prevent cross-contamination;

- The isolation membrane is blown with dry ionic air to remove static electricity from the membrane;

- Ultrasonic sensors are installed for secondary positioning, which can detect heavy and missing pieces;

- Using a servo-driven lamination table, the force between each layer of pole pieces can be evenly distributed;

- Use imported non-marking buffer suction cups to effectively prevent the pole pieces from absorbing and indenting;

- Equipped with diaphragm recovery function and first diaphragm correction function.

Equiment Display