Products Description

The slit extrusion method is used for coating (scraper coating, four-side film maker coating, wire rod coating and other coating processes can be selected). Mainly used in lithium battery substrate, solar photovoltaic film and polymer conductive film, Surface coating of chip substrates in OLED and other fields.

Technical Parameters

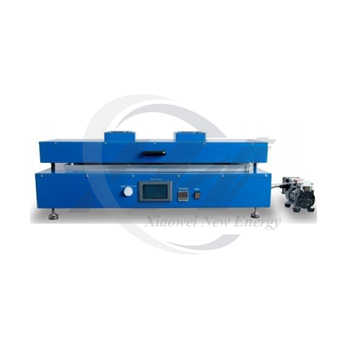

- Coating method: Extruded plate coating machine, standard extruded film applicator;

- Coating stroke is about 300mm, the stroke is stepless set and adjusted in the touch screen;

- Coating drive: motor drive, coating speed in the touch screen stepless setting adjustment;

- Coating speed: 0.5 ~ 20mm/ SEC; * Vacuum plate: aluminum plate with vacuum;

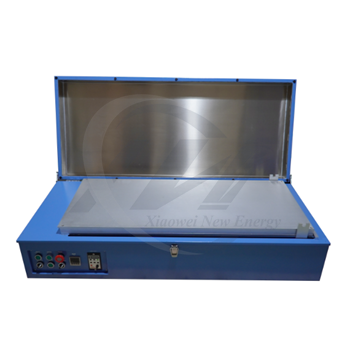

- Vacuum plate size: L415mm×W200mm×H30mm;

- Adjustable blade thickness range: 0~5mm adjustable;

- Injection capacity Max:50ml;

- Feed speed 0.05-5mm/s (injection cylinder piston speed);

- Accuracy: ±3μm, optional display 1μm dial gauge;

- Heating and drying system: room temperature ~ 130℃, digital display temperature controller, accuracy ±1℃;

- 1 built-in oil-free vacuum pump;

- Power supply: 220V/50Hz;

- Weight: 65KG;

- Dimensions: L560mm×W420mmxH370mm;

Product Features

- Extrusion coating process, coating accuracy is high, good consistency;

- Injection pump feeding, feeding system closed, no external interference, paint demand and waste less;

- The coated substrate is a vacuum suction plate with a built-in vacuum pump;

- Easy to disassemble and clean coating mold and feeding system;

- Large area uniform heating to ensure high precision uniform temperature in the chamber;

- Flat plate coating, motor driven scraper coating, coating speed is stable and adjustable;

- Can be used in the glove box, easy to operate, small size, flexible Approximate space;

- PLC. Touch screen control, equipment parameter adjustment, storage, control side is quick.