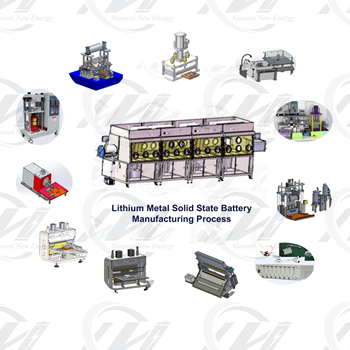

Products Description

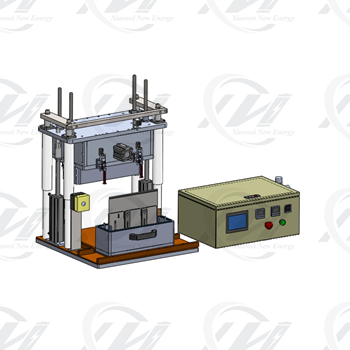

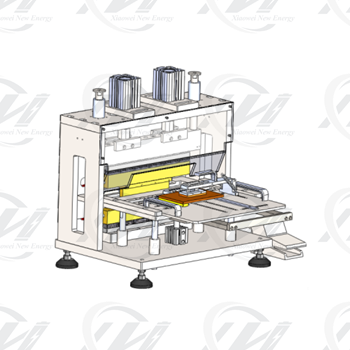

1. Suitable for pre-pumping and hot pressing sealing of flexible packaging lithium battery cell after liquid injection and standing; The vacuum chamber can also be set to vacuum standing function.

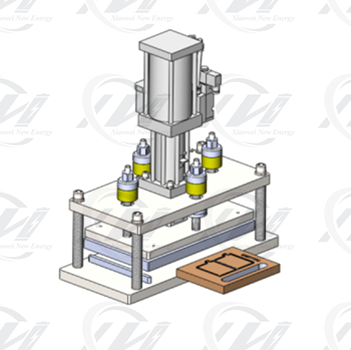

2. Process flow: When the machine is working, manually push the battery fixture equipped with a battery vacuum injection to the vacuum pre-sealing position and position. Start the button, the vacuum presealing mechanism completes the cavity closing, vacuuming, the cylinder pushing the hot head action, completes the hot sealing of the battery air bag, removes the vacuum, and splits the cavity, manually pulls the battery fixture to the loading and unloading position, and takes out the battery that has been injected and pre-sealed. Touch screen Settings: vacuum degree, vacuum time, argon filling pressure and time, head temperature, time, pressure and other parameters.

Technical Parameters

| Vacuum Pre-Sealing Machine For Solid State Lithium Metal Battery Sealing | |

| Overall dimension | L*W*H:About 600*600*820 (mm) (without electric box) |

| Weight | About 120kg |

| Color | Anodized color of aluminum alloy |

| Air source | ≥0.6MPa;100L/Min |

| Vacuum gas source | Vacuum degree; Reach -100Kpa flow rate; Greater than 20m³/h |

| Power | 220V(AC)±10%,50Hz;Power 2Kw |

| Dry air source | Temperature and humidity; Dew point above -45℃, wet removal of dry gas (customer equipped with dew point meter) |

| Load-bearing | >500kg/㎡ |

| Applicable specifications | Length≤300mm, width≤300mm (including the size of the air bag), battery thickness 3-10mm |

| Head length | ≤300mm |

| Seal width | 3-10mm |

| Seal thickness | 0.19-0.3mm |

| Package time | 0-99 seconds(Tunable) |

| Head parallelism | ±0.02mm |

| Head temperature | Room temperature can be adjusted to -260°, compensation can be set, control accuracy ±3 ° C |

| Vacuum degree | ≤-0.095MPa(can set) |

| Capacity | 10-60 EA/H |

Features:

- Can default packaging temperature, and packaging time;

- Alarm function for temperature too low and too high;

- The upper cavity four-column linear bearing guide, accurate accuracy;

- Aluminum oxidation treatment of main components, anti-corrosion and wear-resistant;

- Set light curtain security protection, front and rear baffle protection;

- Independent electric box control, packaging equipment can be easily placed in the glove box;

- The use of programmable controller PLC to achieve automatic control, configuration text display, easy to set up;

- The whole machine is safe, stable, reliable control, easy to operate.