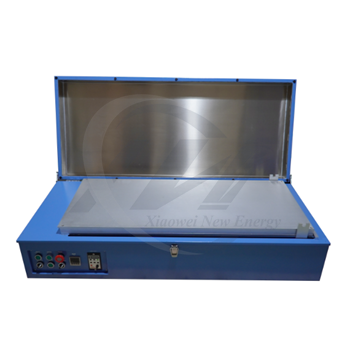

Products Description

It is a device that can flatly coat sheet materials. It can choose coating processes such as blade coating, four-sided film maker coating, extrusion coating, and wire rod coating. It has an infrared heating and drying function, which can realize The synchronous heating of the coating from the bottom layer to the upper layer is beneficial to improving the coating drying efficiency and improving the apparent quality of the coating. The equipment has high coating accuracy and is easy to operate. It can be widely used in industries such as lithium-ion batteries, glue, ink, ceramic films and other functional films. It is an ideal choice for laboratories and research institutions.

Technical Parameters

- Input Voltage:AC 110/220V ±10% / 50/60 Hz;

- Power:1500W;

- Traverse Speed:0~100mm/sec is adjusted Accuracy: 10mm/sec;

- Coating area: W250*800-1000mm, the length can be customized longer;

- Platform Size:300mm L x 200mmW x 30mmH;

- Film Applicator:One 150 mm width micrometer adjustable film applicator is included, with adjustable thickness from 0.01mm~5mm;

- Vacuum Pump:Including one set Vacuum Pump;

- Equipment dimension: L500*W350*H320;

- Weight:50kg;

Product Features

- Motor driven, coating speed is stable and adjustable;

- The vacuum substrate has high precision and good substrate adsorption effect;

- Configure a leftover material collection box to collect leftover materials;

- The built-in exhaust system instantly dissipates heat and eliminates solvents;

- NMP solvent treatment effectively eliminates odors;

- Infrared heating, high drying efficiency and good apparent coating quality;

- Drying temperature and drying time can be set;

- The equipment body and control box are independent, making operation and maintenance easy;

- Various applicators available.