Introduce

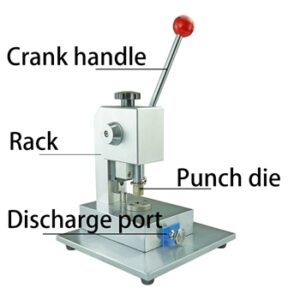

A small button battery punching machine(coin cell punching, disc cutting), specially used for the positive and negative electrode punching process of button batteries. The equipment is compact and convenient. It can be pressed manually and is easy to adjust and install. It is very suitable for button battery research in university laboratories and battery research in scientific research institutions.

Working method: It is composed of upper mold, lower mold, operating handle and other parts. By manually pulling the handle, pressure is generated for punching, and the placed battery electrode are stamped and formed.

coin cell punching machine are often used together coin cell crimping machine .

Manual Coin Cell Punching Machine

Features

- High punching precision and smooth punching

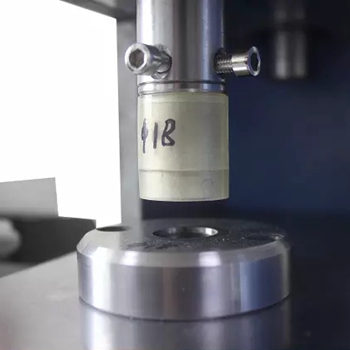

- Mold is easy to replace

- Can punch various battery materials with thickness 0.005 – 0.5 mm(electrode cutting machine)

- Small size, easy to operate, can be operated in the glove box

- Exquisite appearanc

Main Parameters

- Applicable batteries: All kinds of AG, CR, LIR button batteries, 2032, 2025, 2016 and other model pole pieces punched;

- Punching accuracy: ±0.015mm; (different types of grinding tools can be replaced at will)

- It can punch various battery materials with a thickness of 0.005 – 0.5 mm;

- Mold material: high-quality mold steel chromium steel, heat treated to HRC62 hardness;

- Overall size: 310 (H) × 280 (W) × 250 (D) mm;

- Machine weight: about 13KG.