Battery Process

More Custom Items

Pilot Line & Production Line-Cylindrical Cell Battery

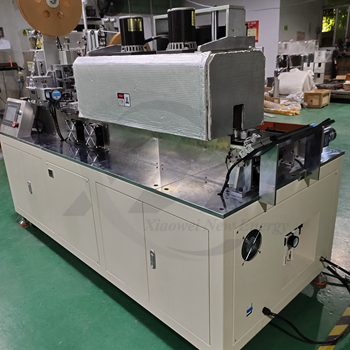

Xiaowei new energy’s cylindrical battery assembly production line can be fully automatic/semi-automatic and multi-station to achieve a certain scale of production of 18650, 21700, 26650, 32650, 4680, 4690 and other models of batteries. We have multiple solutions to complete the production of batteries. , fully automatic assembly lines, and semi-automatic single equipment with manual assembly to complete the assembly. The equipment included in the cylindrical assembly line is:Winding machine, cylindrical inserting can machine, grooving machine, cap welding machine, shrink film machine etc.

Xiaowei Cylindrical Cell Battery Production Process

Xiaowei new energy’s cylindrical battery assembly production line can be fully automatic/semi-automatic and multi-station to achieve a certain scale of production of 18650, 21700, 26650, 32650, 4680, 4690 and other models of batteries. We have multiple solutions to complete the production of batteries. , fully automatic assembly lines, and semi-automatic single equipment with manual assembly to complete the assembly. The equipment included in the cylindrical assembly line is:Winding machine, cylindrical inserting can machine, grooving machine, cap welding machine, shrink film machine etc.

Cylindrical cell battery assembly process for battery polit production

Cylindrical battery automatic assembly line: The process of assembling bare cells into the casing and welding the cap. This system of XIaowei is suitable for the pilot production scale of cylindrical batteries, with a production capacity of 40-70ppm/min.

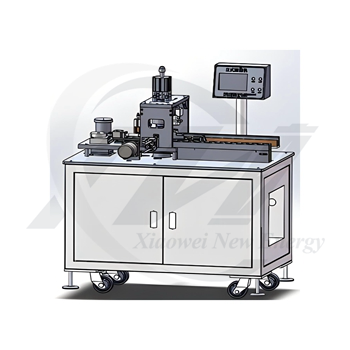

Automatic production of lithium battery electrode

The Electrode making machine is suitable for cutting, producing and forming, collecting and transferring diaphragm cassettes of lithium metal strips/lithium copper composite strips for lithium battery research and making.

Roll the prepared electrode into a cylindrical shape

The fully automatic lithium battery winding machine is used to wind lithium battery cells. It is a machine that assembles the positive electrode sheet, negative electrode sheet and separator of the battery into a core package in a continuous rotating manner.

Cylindrical battery cell into case

Cylindrical cell inserting can machine is used to automatically flush out the bottom pad and automatically insert the battery core into the steel case. It has a humanized structure, simple operation, stable, reliable and efficient, and is suitable for mass production.

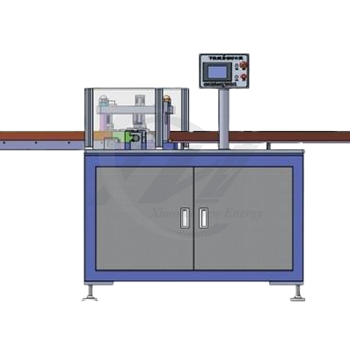

Roll groove the cylindrical battery shell and open it

Automatic cylindrical cell grooving machine: Battery rounding groove used for battery cells after being inserted into the case and for welding the battery cells to the bottom of the battery shell;

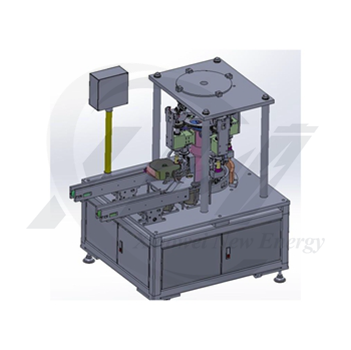

Used for laser welding of tabs and caps of cylindrical batteries;

Automatic cap welding machine of cylindrical batteries: The function of this equipment is to weld single battery tabs and caps, using laser welding technology. In addition, xiaowei can also provide manual ultrasonic welding systems and automatic ultrasonic welding systems.

Stamp and seal the cylindrical battery steel case that has been filled with liquid and capped

Automatic cylindrical battery sealing machine used in pilot line production: The equipment mainly punches and seals the cylindrical battery steel shell after liquid injection.

After the cylindrical battery is sealed, the labeling and shrink film process is completed

Cylindrical Battery Labeling&Shrink Film Machine: Suitable for 18650 cylindrical steel shell battery case heat shrink tube, adding positive insulating pad, and heat shrinking.