Products Description

Scope of application: All kinds of common battery powder and liquid mixing and dispersing, and finally get a evenly mixed battery slurry. Ideal for high viscosity processes. Suitable for working condition viscosity range ≤ 1.2 million cP.

Technical Parameters

Lower barrel unit:

- Total design volume: 45L;

- Effective volume: 15-30L;

- Inner diameter of container: 400mm;

- Inside depth: 360mm;

- Container material: Part in contact with material 304;

- Temperature control jacket form: barrel wall single jacket, used for cooling or heating; Barrel bottom single jacket for cooling or heating;

- Temperature control jacket interface: G1/2″, equipped with quick-opening loose connector, jacket pressure ≤0.4MPa;

- Temperature control jacket circulation system: customer’s own, it is recommended that jacket inlet temperature ≤8℃, cooling water flow > 15L/min

- Discharge form: a G1″ three-piece discharge ball valve at the bottom of the barrel;

- Design ambient temperature: -10 ~ +120°C;

- Moving mode: caster mobile.

Mixing unit:

- Operating frequency: 5-50hz;

- Mixing power: 4kw;

- Mixing impeller speed: 6-67rpm;

- Planet box speed: 4-42rpm;

- Impeller diameter: 223mm;

- Impeller type: spiral twist precision casting and processing guarantee 90° helix;

- Mixing paddle material: 304;

- Impeller linear speed: 0.09-0.9m/s;

- Number of mixing paddles: 2;

- Paddle to paddle distance: 9±2mm;

- Distance between paddle and barrel wall: 5±1mm;

- Distance between paddle and barrel bottom: 3±1mm.

Dispersed unit:

- Operating frequency: 5-50hz;

- Distributed power: 4kw;

- Dispersion speed: 546-5460rpm;

- Dispersion disc diameter: 80mm;

- Dispersion disk style: zigzag;

- Dispersion disc material: 304;

- Dispersion linear velocity: 2.2-22m/s;

- Number of dispersion disks: 2;

- Number of dispersion axes: 1

Scraping unit:

- Wall scraping bracket material: 304;

- Scraping sheet material: polytetrafluoroethylene;

- Scraping speed: consistent with the planetary box speed;

- Detachable or not: detachable design (wall scraping must be removed during high viscosity process).

Base and lifting parts:

- Component material: carbon steel for high rigidity structure;

- Lifting mode: electric lifting;

- Lifting guide: high precision linear guide;

- Lifting stroke: ≤500mm.

Upper drum unit:

- Upper barrel material: 304;

- Powder feeding port: DN75 with sight mirror quickly install one;

- Liquid charging port: shared with powder;

- Spot light port: DN70 tempered glass sight mirror;

- Vacuum port: one G3/4 “inner wire;

- Exhaust port: one G1/2 “inner wire;

- Digital display vacuum gauge port: one M14×1.5 inner filament metric tooth interface;

Control system:

- Electric cabinet: used to house low-voltage electrical parts such as frequency converters;

- Manual operation panel: used to place buttons, knobs, instruments, etc;

- Power supply: AC 3 x 380V±5%, 50Hz;

- Control mode: electric control + hydraulic control;

- Power control and speed regulation mode: inverter start and control;

- Cooling method: air cooling and liquid cooling;

- Operation mode: touch screen operation;

- Digital temperature display table: material temperature;

- Emergency stop button: one alarm system: overtemperature alarm, overtemperature alarm stop, alarm close;

- Speed display: The touch screen displays the speed;

- Power indicator: one;

- Timer: one that controls both dispersion and agitation;

- Note: If you select the HMI system configuration, the control system related content is integrated into the touch screen control.

Safety interlocking system:

- Scram: After you press the SCram switch, the device stops immediately and no operation can be performed;

- Start mixing at low speed. Mixing: you can turn while lifting the bucket;

- High speed dispersion: the barrel can be turned only when it is raised into position;

- Safety lock in operation: when the machine is running and mixing, the mixing barrel cannot be lowered or opened;

- Prevent vacuum pipeline backflow: Special vacuum buffer tank design, can effectively prevent the vacuum pump oil backflow into the mixing tank phenomenon;

- Operation failure stop: inverter comes with overload, overcurrent, overvoltage, leakage, lack of equal protection;

- Stirring bucket lift: The stirring bucket can be lifted only after it is in place;

- No vacuum is discharged in the mixing bucket (no normal pressure is restored);

- The high speed dispersion can only be started after the stirring bucket is lifted into place;

- After the mixing drum is raised in place, it is equipped with a locking protection system to prevent the mixing drum from falling abnormally after rising to a high level during work;

- The dry mixing stage requires the stirring paddle to rotate while lifting the barrel.

Other instructions:

- Temperature probe: Pt100;

- Temperature measuring method: barrel wall temperature measuring head detects material temperature;

- Transmission parts bearings: high-speed parts for imported bearings, low-speed parts for domestic bearings;

- Oil seal: domestic brand, static seal with O-ring, dynamic seal with mechanical seal;

- Lubricating oil: domestic brand;

- Mechanical seal lubricating oil: imported brand;

- Cylinder: domestic brand;

- Oil station: domestic brand;

- Valve: domestic brand;

- Vacuum retention: -0.098Mpa, the pressure is higher than -0.085Mpa for 24 hours, and does not leak into the barrel;

- Total host power: > 10kw;

- Weight: About 1150kg;

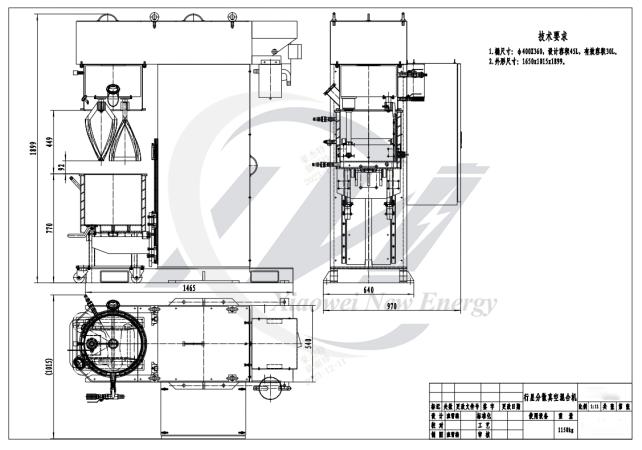

- Equipment dimensions: L 1650mm x W 1015mm x H 1899mm;

- Appearance color: beige;

- Ground load: 1000kg/㎡;

| List of random wearing parts: | |||||

| No | Name | Specification | Material | Quantity | Remark |

| 1. | Cover sealing rubber ring | ΦD×ΦN | Silica gel | 1 | Specifications and corresponding models, according to the supplier’s standards |

| 2. | Mirror seat seal ring | Silica gel | 2 | ||

| 3. | Charging port seal gasket | Silica gel | 1 | ||

| 4. | High speed mechanical seal | C+SiC | 1 | ||

| 5. | High speed synchronous belt | rubber | 1 set | ||

| 6. | Wiper board | Teflon | 1 | ||

| 7. | Sight glass sheet | Tempered type | 2pieces | ||

| Supporting conditions: | ||

| No | Project name | Standard requirement |

| 1. | Workshop height | >3M;The lifting of the machine requires a certain height guarantee and consideration of maintenance needs; Neat and smooth. |

| 2. | Doorway size | Height: >2.5M; Width: >1.5M; To ensure machine transport in and out. |

| 3. | Cooling water | Ensure cooling requirements, preferably with a forced cooling water supply system; In winter, hot water is needed for heat preservation. |

| 4. | Heating | In view of the cold weather in the north in winter, in order to make the hydraulic oil used for lifting and lowering not condense, the indoor temperature must be ensured. 20 ºC to ensure the smooth lifting of the machine; And ensure the normal operation of the lubrication system. |

| 5. | Installation space | Refer to the general drawing of the scheme for layout. |

| 6. | Air source | 5 ~ 7 kgf/cm², 100 l/min; Pneumatic pump drive and other occasions. |

| 7. | Other | No corrosive gas, liquid, explosive gas. |