Introduce

pouch cell sealer machine is mainly suitable for the packaging of the top side and side of the flexible packaging lithium battery.

The heat is transferred to the head (copper) through the heating pipe, and the heat conduction effect is applied to the aluminum-plastic film of the lithium battery Above, under the action of a certain pressure, it is heated to become soft and close to the melting state to complete the pressure fusion joint.

About 3 devices for laboratory research on lithium battery pouch cell battery sealing.

- (top&side) pouch cell sealer machine;

- vacuum pre-sealer machine;

- final sealer machine for pouch cell.

More pouch cell lab research equiment video.

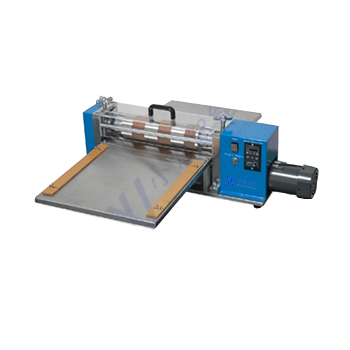

Pouch cell sealer(top&side) machine

Features

- The temperature of the head can be adjusted and maintained by thermocouple and thermostat Constant temperature;

- Built-in pressure gauge;

- The sealing edge is firm, the sealing mark is even and uniform, the packaging shape is beautiful and unique safety protection, anti-hot design;

- More than 50% energy saving with similar products;

- The pouch cell sealing tool achieves top sealing and side sealing without changing the mold;

- Simple operation, safe and reliable, beautiful appearance, small size;

Main Parameters

- Head length: ≤200mm;

- Seal width: standard 5mm (can be customized according to demand) edge thickness: 0.15~0.3mm;

- Applicable specifications: Side seal s200mm;

- Top seal ≤200mm (including air bag) (can be customized according to demand);

- Upper mold temperature: Max300 ° C 200 ° C Lower mold temperature: Max300 ° C 160 ° C Heat seal pressure: 0.5~0.7MPa adjustable;

- Package time: Standard 25~35(0-99s adjustable) Power supply: AC220V/50Hz;

- Power: 900W;

- Dimensions: L320xW320xH500mm;

- Equipment weight: 30KG;