Products Description

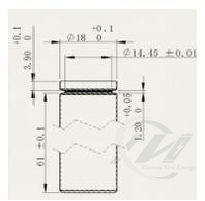

Automatic cylindrical cell grooving machine: Battery rounding groove used for battery cells after being inserted into the case and for welding the battery cells to the bottom of the battery shell;

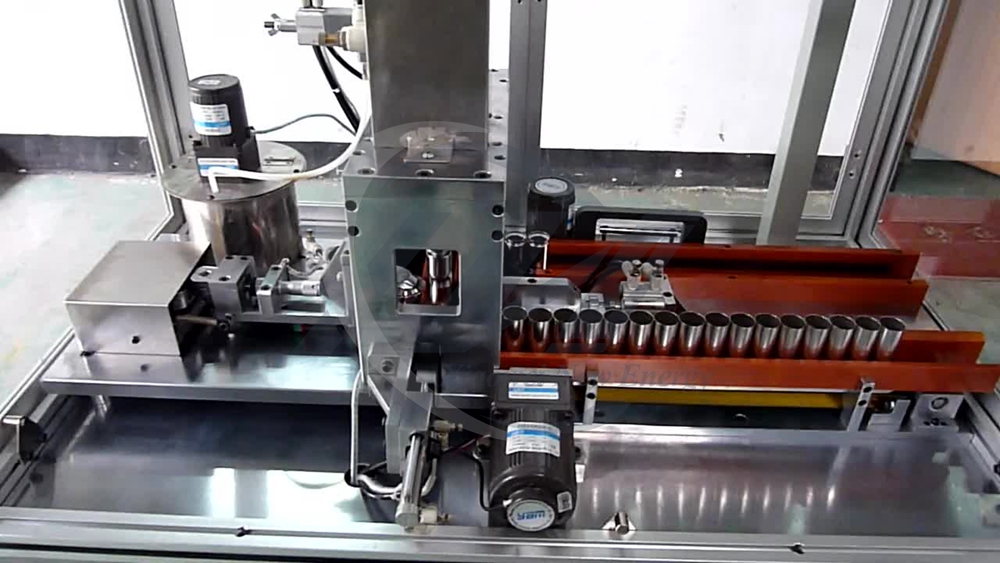

Equipment function: In the front process, the battery uses a magnetic rod to suck the entire battery into the conveyor belt. When the conveyor belt ends, the cylinder pushes the battery to the rolling groove station area. Roll groove grinding tools groove batteries. After rolling the groove, push it to the discharging conveyor belt and repeat the next cycle.

This equipment (Automatic Grooving machine for battery polit Production) is exclusively developed by Xiaowei after years of technical research and cooperation with a strong technical team. The coating of the battery case will not fall off after rolling grooving; in the rolling grooving mechanism, we use cam feed , not affected by air pressure changes, micrometer adjustment ensures size. When ensuring the change in caliber, we use the method of covering the battery case to keep the caliber of the battery case within the size range of the battery sleeve. The structure is as follows:

Technical Parameters

| Working temperature range | 0~40 |

| Humidity | below 75% |

| Venue | No pollution and strong electromagnetic interference |

| Maximum device size | 1000mm(L)x600mm(W)x1500mm(H) |

| Weight | about 300Kg |

| Working voltage | AC380V±10V 50Hz |

| Power consumption | ≤1.2KV |

| Air source | 0.6MPa-0.8MPa (dry and constant compressed air) |

| Capacity | 30-40ppm |

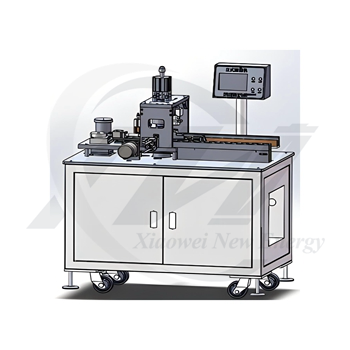

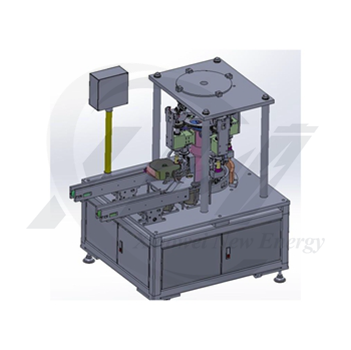

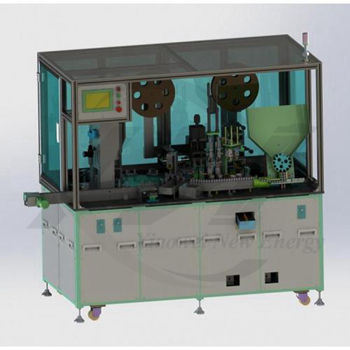

Equiment Display