Products Description

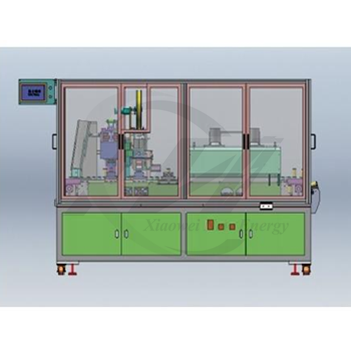

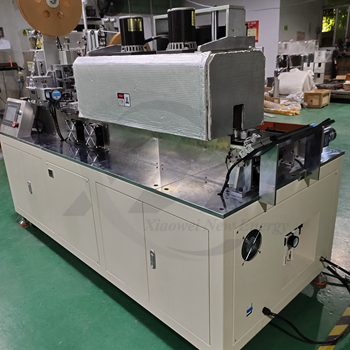

Cylindrical Battery Labeling&Shrink Film Machine: Suitable for 18650 cylindrical steel shell battery case heat shrink tube, adding positive insulating pad, and heat shrinking.

The battery needs to be manually loaded from the previous process, and then the battery is automatically pushed onto the chain by a cylinder. The heat shrinkable tube is prepared, cut, assembled, punched, and the top insulation pad is added. After hot air shrinkage, it is completed.

Front and labeling&shrink film effects:

Technical Parameters

| Automatic Cylindrical Cell Labeling Machine For Cylindrical Cell Battery Polit Production | |

| Power supply | AC380V*4P/50Hz Power: 10KW. |

| Compressed air | ≥0.6 MPa 5L/min |

| Equipment weight | about 800KG |

| Dimensions | 2270Lx850Wx1950H (mm) (excluding loading and unloading mechanism) |

| Applicable batteries | 18650, 21700, 32650 and other steel shell batteries (can be customized) |

| Heat shrinkable tube requirements | incoming roll material, width 29.7±0.05mm, single side thickness 0.09±0.01mm |

| Width of insulation sheet | Incoming roll material, width 20±0.05m (no splices allowed) |

| Shrinkage temperature | adjustable from room temperature to 200 degrees |

| Equipment production capacity | 60±5PPM |

| Sleeve labeling First pass rate | ≥97% |

| Equipment utilization rate | ≥95% |

| Casing cutting accuracy | ±0.25 mm |

| Working environment | temperature 10~30℃, humidity 30~70% |

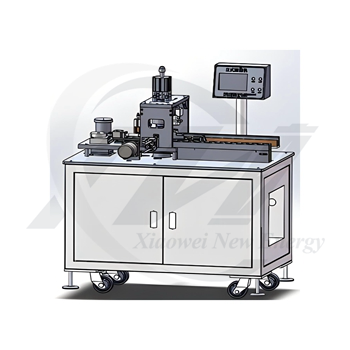

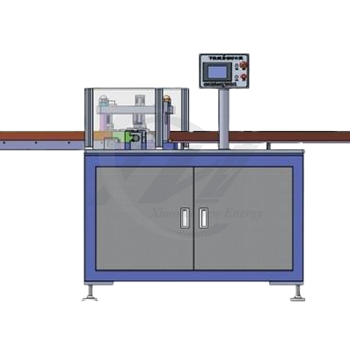

Equiment Display