Products Description

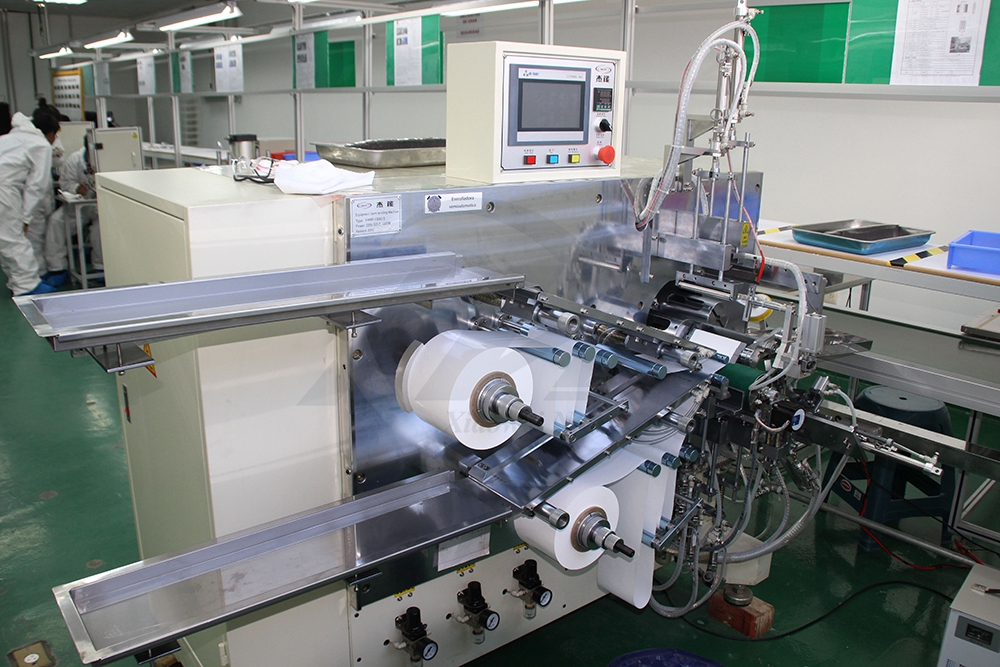

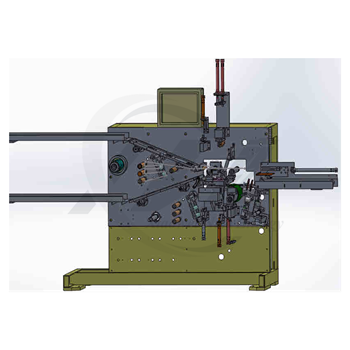

This semi-automatic winding machine has a continuous diaphragm and is controlled by an imported precision proportional valve. The tension is digitally set. During operation, the tension is automatically adjusted according to the set speed, number of turns and needle width. The battery core winding process is evenly stressed. The inner ring of the battery core is truly S-shaped.

Work flow of semi-automatic electrode winding machine:

- Two layers of separator are pre-rolled on the rolling needle;

- Manually guide the positive and negative electrode sheets into the winding part and overlap them with the separator;

- winding;

- Auto-adhesive termination tape;

- Finish Winding process.

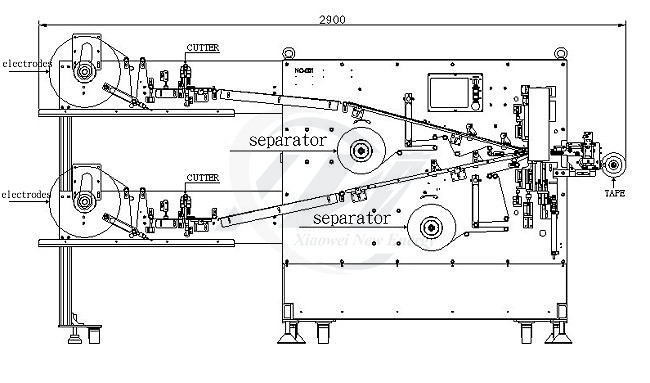

Technical Parameters

| Semi-Automatic Electrode Winding Machine | |||

| Parameter name | Technical Parameters | Unit | Remark |

| Needle combination width | 30-100 | mm | |

| Electrode piece length | 300-2000 | mm | |

| Electrode piece width | 28-148/48-198 | mm | Can be customized |

| Diaphragm width | 30-150/50-200 | mm | Can be customized |

| Tape width | 15-80 | mm | Post vertically |

| Speed | 4-6 | Pcs/min | Depends on specific specifications |

| Power supply | AC220V 50HZ | ||

| Total equipment power | 1.0 | kw | |

| Dimensions | 2000L*1600W*1450H | mm | Excluding trough extension length |

| Gas source | 0.4-0.6 | MPa | |

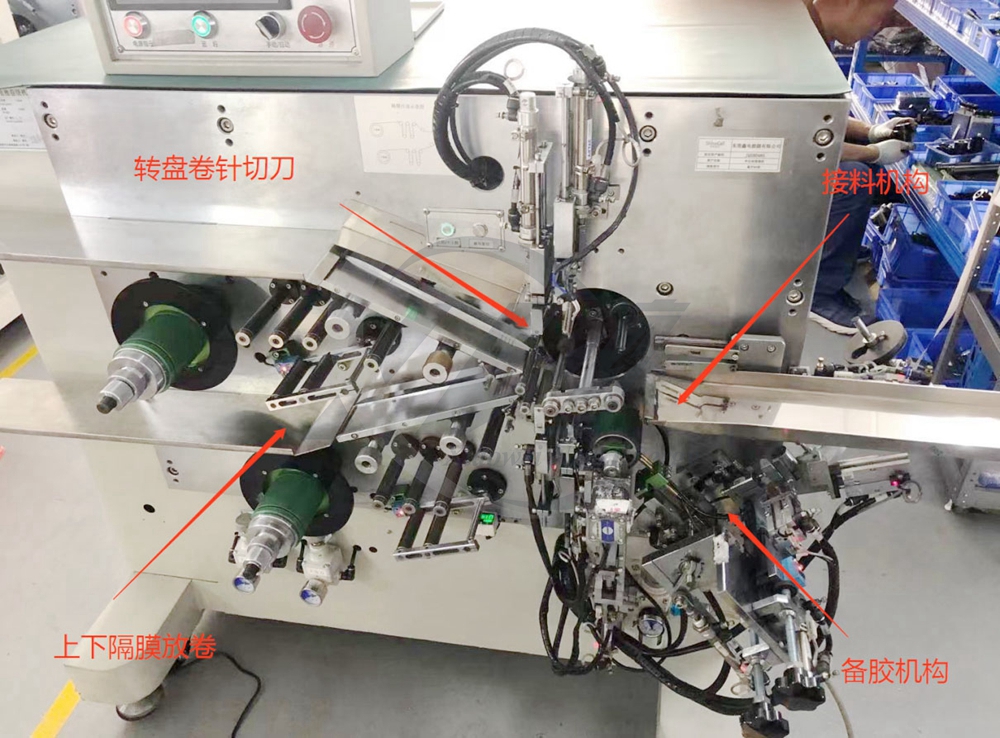

Features:

- Manually introduce pole pieces, automatic winding, automatic gluing and automatic blanking;

-

It adopts double rolling needle combination and double station structure, and the rolling needle width can be adjusted;

-

The winding is directly driven by a stepper motor, which has high reliability and more stable operation;

-

The diaphragm adopts active discharge and the tension is linear and constant;

-

The outer cover of the diaphragm or the outer cover of the pole piece can be adjusted on the panel, which is extremely convenient;

-

High winding accuracy, diaphragm and pole piece alignment accuracy;

-

Using imported PLC controller and human-machine interface control, the operation is simple, intuitive and convenient;

-

The rolled-out battery core has no damage, core pulling or pole piece misalignment, and the glue application is stable and reliable;

-

If any abnormality occurs during work, the equipment will automatically alarm and display the fault location;

-

Detail processing shows humanization, easy operation and better stability.

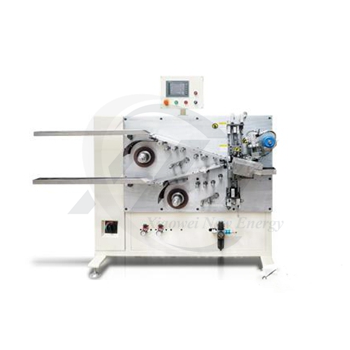

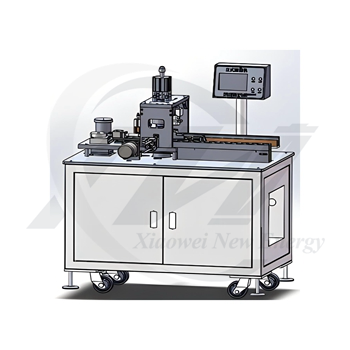

Equiment Display