Products Description

Cylindrical battery automatic assembly line: The process of assembling bare cells into the casing and welding the cap. This system of XIaowei is suitable for the pilot production scale of cylindrical batteries, with a production capacity of 40-70ppm/min.

Mainly used for automatic bottom pad flushing, cell detection, battery core insertion into steel shell, automatic bottom welding, automatic top sheet flushing, automatic rolling groove glue application, automatic laser welding of caps, and box collection of welded caps for cylindrical lithium batteries.

1. The batteries cell with soldering pins manually inserted into the hopper are automatically transferred to the next station;

2. Fully automatic spot bottom welding and pin removal (automatic tab shaping);

3. Automatic flushing and short circuit testing;

4. Automatic rolling groove function and automatic gluing;

5. Automatic laser cap welding system;

6. Assembly process completed.

Technical Parameters

| Automatic Cylindrical Cell Assembly Line For Polit Battery Production | |

| Rated voltage | 380V 50Hz |

| Rated power | 10kw |

| Working air pressure | 5-7kgf/cm2 |

| Welding pin diameter | 2.0-3.0mm |

| Insulation sheet thickness | 0.20mm coil material |

| Application scope | 10/14/17/18/21/26/32 |

| Working efficiency | 40-45ppm/min (single station) 70 ppm/min (double station) |

| Number of operators | 2-3 people |

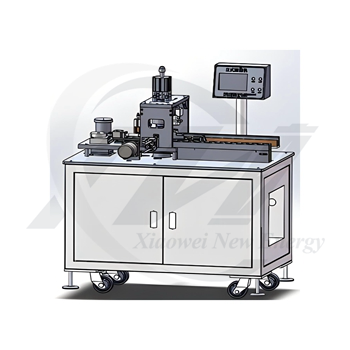

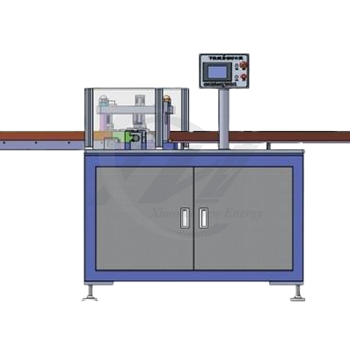

| Product size | 1800*800*1600mm (single station) 1550*1100*1800mm (double station) |

Equiment Display