Introduce

Battery Stacking machine is used for the lamination process of battery cells to laminate the positive and negative electrode sheets and separators.

“Z” stacking is a device that can be used in the stacking process of lithium-ion batteries.

The equipment adopts an automatic tension control system for the isolation film. The cylinder drives the diaphragm to move left and right to achieve “Z” shaped stacking. The cantilever design is easy to operate. Compared with manual stacking machine, this equipment has the characteristics of high stacking efficiency, good stacking neatness, and a wide range of battery sizes. It is an ideal choice for R&D sample production and small batch trial production equipment.

pouch cell battery winding machine for li-ion battery winding process.

Battery/electrode stacking machine in pouch cell battery production line video.

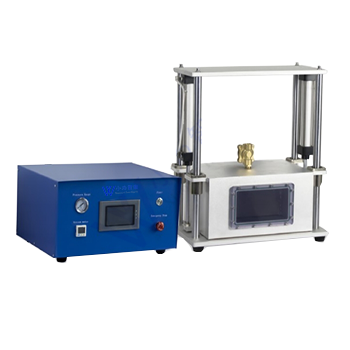

Semi-Automatic stacking machine

Features

- Easy to adjust, operate and maintain the machine;

- Suitable for large size range of cell stacking;

- Simple tension control;

- Automatic counting, zero function;

- Automatically keep the last used parameter status function after power failure and no use;

- Large range of battery sizes for the whole machine;

- Pedal switch is used to control cylinder action;

- The machine is easy to adjust, operate and maintain;

- High working efficiency, with digital timer;

- Table type, can be placed on the ordinary desktop, exquisite and beautiful appearance;

Main Parameters

- Lamination accuracy: uniformity is better than ±0.5mm;

- Stack size (including electrode length):Min L44mm*W44mm (The smaller need to replace the press), Max.L200mm*W150mm (Pole ear on long side)

- Laminated thickness: Max.12mm (the adjustment plate needs to be replaced if it is thicker);

- Diaphragm diameter: Max.220mm;

- Installation size: L512*W820*H580mm;

- Weight: About 50Kg;

- Power supply: 220V;

- Air source: 0.4~0.6MPa compressed air;