Battery Process

More Custom Items

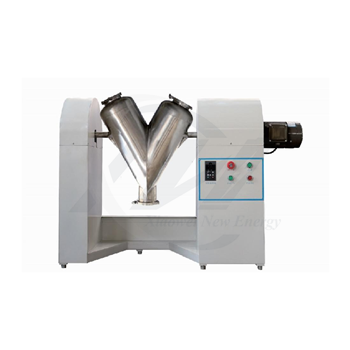

Lab Mixing Machine

Xiaowei provides a variety of laboratory battery mixing machine (50ml – 10L) that can be supported, and can also provide customers with mixers of different capacities, laboratory conventional mixers, vacuum mixers, planetary mixers machine.

xiaowei provides a variety of laboratory equipment for new energy battery research